As the market scale of LED displays continues to expand, the technological iteration of cabinets has accelerated at a remarkable pace. LED display cabinets can be classified in multiple ways.

The core distinction is closely related to their operating environment:

- By waterproof performance, they are divided into fully waterproof cabinets and standard cabinets;

- By installation and maintenance methods, they include front-access cabinets, dual-sided display cabinets, and special-shaped structure cabinets, among others.

Below, we will guide you the most common cabinet materials and application scenarios.

Table of Contents

ToggleIron LED Display Cabinets

Iron LED cabinets are crafted from pure iron. They are the longest-serving type in the industry. There is available in two variants: sealed and standard.

For cabinets of the same size, sealed iron models are both heavier and more expensive than their standard counterparts. However, their key drawbacks are undeniable: their substantial weight and large volume increase construction complexity, necessitating mechanical assistance for installation.

Additionally, long-term use leads to oxidation and rust, resulting in poor reliability. It is the factors that have gradually phased them out of mainstream markets. Currently, they only linger in some low-end applications. Although they have these advantages of low cost and short production cycles, but their market share continues to shrink as better alternatives emerge.

Alloy-Based LED display Cabinets

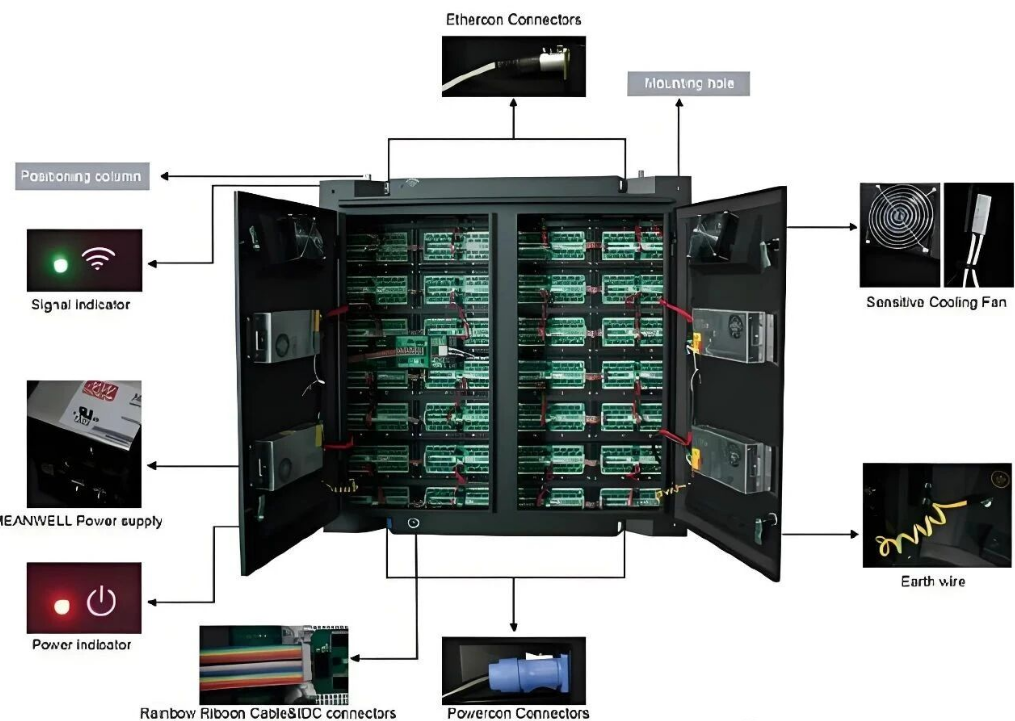

Die-Cast Aluminum LED Cabinets

Die-cast aluminum cabinets use high-purity aluminum ingots with a purity of up to 92% as the core raw material, mixed with alloying elements such as zinc to enhance hardness and strength.

The manufacturing process follows a standardized workflow: one-time die-casting molding → trimming and polishing of mold joint residues → precision surface treatment.

By optimizing the design of connectors, hidden wire grooves, and hangers, these cabinets have an integrated installation effect for modules and a seamless, aesthetically pleasing overall screen splicing.

Their core performance advantages are highly prominent:

- High strength and superior heat dissipation;

- High precision, high material utilization

- Controllable production costs.

The LED display cabinets are lightweight, visually appealing. It is easy to install, with strong environmental adaptability. They have an IP rating of IP65~IP67, an operating temperature range of -20℃ to 60℃, and a humidity tolerance of 10% to 90%.

Moreover, they can flexibly match various LED modules and support personalized customization. Therefore, they are widely used in indoor, outdoor, and rental LED display markets.

Magnesium Alloy LED Cabinets

Magnesium alloy cabinets use magnesium as the primary raw material, blended with alloying elements such as zinc, aluminum, manganese, and small amounts of zirconium or cadmium. Compared to die-cast aluminum cabinets, they offer even more compelling advantages:

- Higher strength

- better heat dissipation

- superior shock absorption

- stronger impact load resistance.

- Enhanced acid and alkali corrosion resistance.

- Excellent cost-effectiveness and lighter weight.

So, they are particularly suitable for robotic assembly scenarios. In addition, they have a strong competitive edge in the market.

New Material-Based Cabinets

Nanopolymer materials combine the size effect, surface effect, and quantum effect of nanoparticles with the advantages of polymer matrix materials. They are lightweight, low density, easy modification, and simple processing.

Nanopolymer LED cabinets inherit the strengths of both components. Therefore, they have exceptional impact resistance, seismic performance, and shatterproof capabilities.

Compared to die-cast aluminum LED display cabinets, nanopolymer cabinets offer distinct benefits: they are lighter and 20% more cost-effective. Therefore, they are an ideal choice for applications prioritizing lightweight design and budget control.

Carbon Fiber LED Cabinets

Carbon fiber is a high-strength, high-modulus fiber with a carbon content exceeding 90%. It is produced through high-temperature oxidation and carbonization. It has low density and extremely high strength and modulus along the fiber axis. Therefore, it is a staple in aerospace, high-end sports equipment, and other high-performance fields.

Carbon fiber LED cabinets represent the pinnacle of cabinet technology, with industry-leading performance advantages: Exceptional resistance to high temperatures, wear, corrosion, and tensile forces.

Ultra-lightweight and thin design:

30% lighter than die-cast aluminum cabinets, they are currently the thinnest and lightest cabinet type. They offer significant load-bearing advantages for ultra-large screen installations.

Fully modular design:

In addition to flat installations, they support special-shaped configurations such as curved, folded, and multi-angle setups, compatible with both standard LED modules and flexible modules that can be arbitrarily deformed and spliced.

Their lightweight nature greatly simplifies transportation, installation, and disassembly processes, effectively solving the load-bearing challenges of ultra-large-scale LED displays.

Therefore, they are widely used in large-area installation scenarios such as stadiums, outdoor billboards, and architectural facades.

Core Performance Comparison Analysis

To intuitively showcase the practical value of each cabinet type, we make the following table. You can know the key technical parameters and performance indicators of cabinets made from different materials:

| Type | Density (g/cm³) | Typical Thickness (cm) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation at Break (%) | Heat Dissipation Coefficient (W/(m·k)) | Corrosion Resistance | Heat Resistance (℃) | Typical Cost (RMB/Set) |

|---|---|---|---|---|---|---|---|---|---|

| Iron Cabinet | 7.8 | 8.5 | 170~270 | 157~170 | 50 | 81.1 | Poor | 450 | 155 |

| Die-Cast Aluminum | 2.7~2.84 | 6.0~8.0 | 265~370 | 70 | 4.3 | 96.2~113 | Average | 650 | 238 |

| Magnesium Alloy | 1.8 | 7.5 | 305~315 | 45~50 | 15 | 154.5 | Good | 150 | 215 |

| Nanopolymer | 0.8~2 | 2~7 | 1200 | 110~135 | 1000 | —— | Very Good | —— | 190 |

| Carbon Fiber | 1.7 | 1 | 3530 | ≥220 | 1.5 | 155 | Excellent | 2500 | 285 |

Key Insights from the Comparison

As evident from the data, carbon fiber LED cabinets hold an absolute advantage in core indicators such as weight, thickness, tensile strength, heat dissipation, corrosion resistance, and heat resistance. Therefore, it can cover a broader range of special application scenarios. Their only drawback is the relatively high cost, which positions them at the upper end of the price.

Die-cast aluminum cabinets remain a popular choice for mainstream applications due to their balanced performance, cost-effectiveness, and wide compatibility with modules.

Magnesium alloy cabinets have good robotic assembly and high-reliability scenarios, while nanopolymer cabinets offer a cost-effective solution for lightweight requirements. However, Despite Iron cabinets low cost, they are gradually being phased out due to their poor corrosion resistance and heavy weight.

Market Trends and Future Outlook

The continuous expansion of the LED display market has driven the diversification of application scenarios. From small indoor displays to large-scale outdoor billboards and curved architectural screens, they have more demand for high-performance cabinets.

Lightweight design, thinness, easy installation, and high reliability have emerged as the core development directions for cabinet technology.

Carbon fiber LED cabinets have ultra-lightweight, high strength, excellent corrosion resistance, and modular flexibility. They perfectly align with future market demands. While their cost is relatively high, economies of scale from increased adoption are expected to drive significant cost reductions in the coming years.

As a result, carbon fiber LED cabinets are poised to become one of the core development directions in the LED cabinet industry, particularly for large-scale, high-end applications.

In summary

From traditional iron to advanced carbon fiber, each material have specific market needs, and the ongoing innovation in materials will continue to push the boundaries of what LED displays can achieve.

For businesses and project managers, you can choosse each LED display cabinet according to your needs.