Stadiums are more than just venues. They’re immersive hubs for unforgettable moments. However, Stadium outdoor LED displays meet the unique demands of sports venues. Today,Let’s guide you how we’ve engineered a stadium environments solution.

Table of Contents

ToggleProduct Requirements:

Stadium displays face unique challenges:

- 24/7 operation

- large viewing distances

- exposure to the elements.

- The display must run continuously day and night.

- Support both synchronous and asynchronous playback for flexible content management. Deliver crisp, high-definition video, images, and text.

- with zero pixelation or grayscale distortion,even for viewers between 6 and 300 meters away.

As a leading led display manufacturer, SightLED brings many professioal stadium projects. For this project, we recommend a P4 outdoor SMD full-color LED display.T hey have perfect blend of image clarity, structural efficiency, and cost-effectiveness.

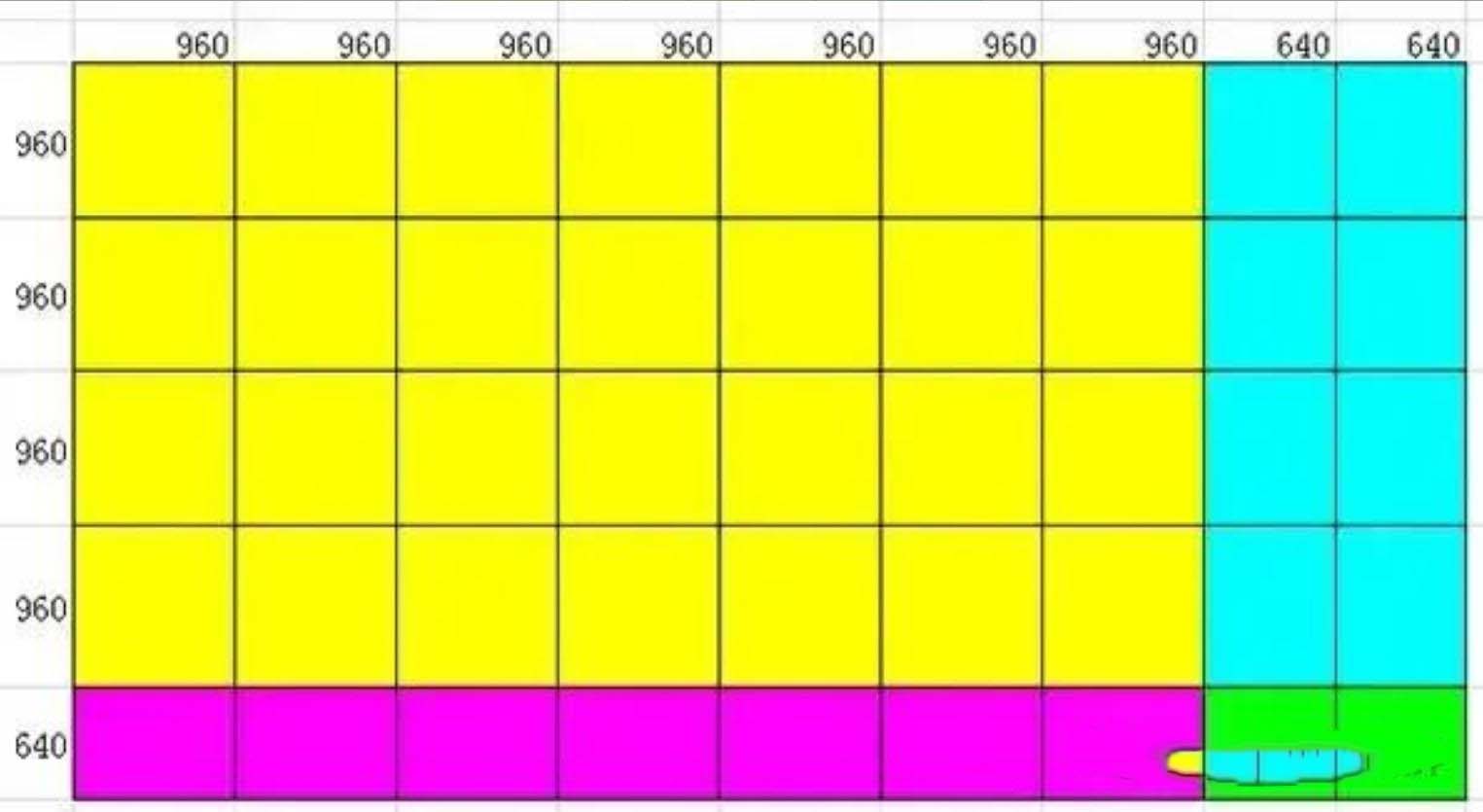

To keep front-end video production manageable while ensuring distortion-free visuals, we’ve optimized the resolution to ultra-high definition (UHD). Two options are available:

- 2160×1200 pixels.

- 2640×1440 pixels.

This design uses the 2160×1200 configuration for large-scale viewing.

Display Specifications:

Every dimension and parameter is designed to maximize viewer experience and structural practicality:

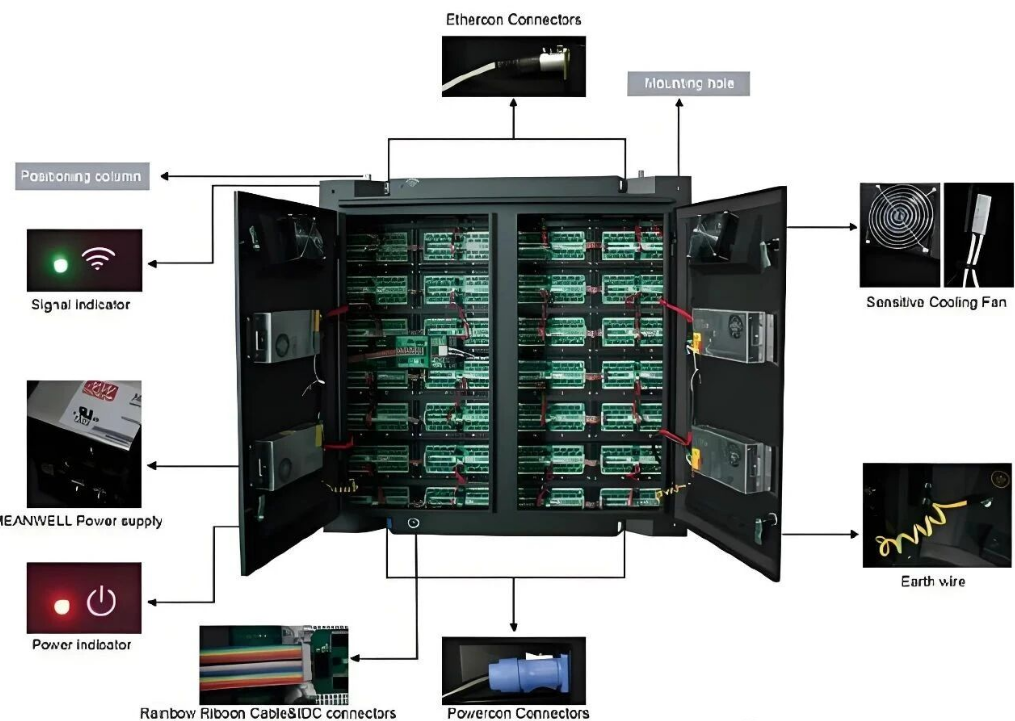

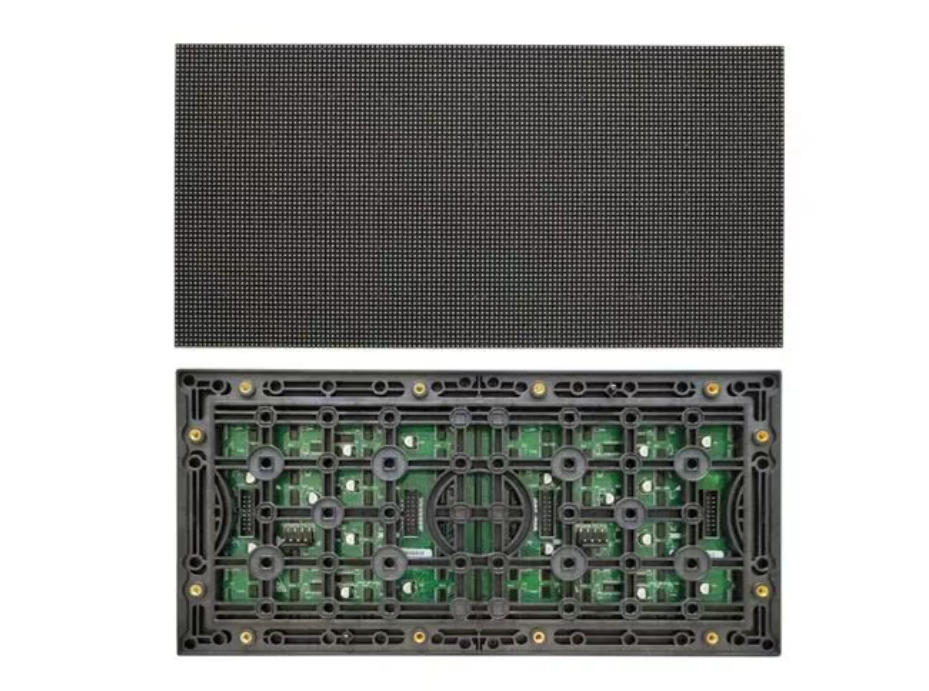

Our P4 outdoor LED display has below features:

- SMD packaging

- Waterproof sheet metal cabinet

- Brightness over 6000 cd/m².

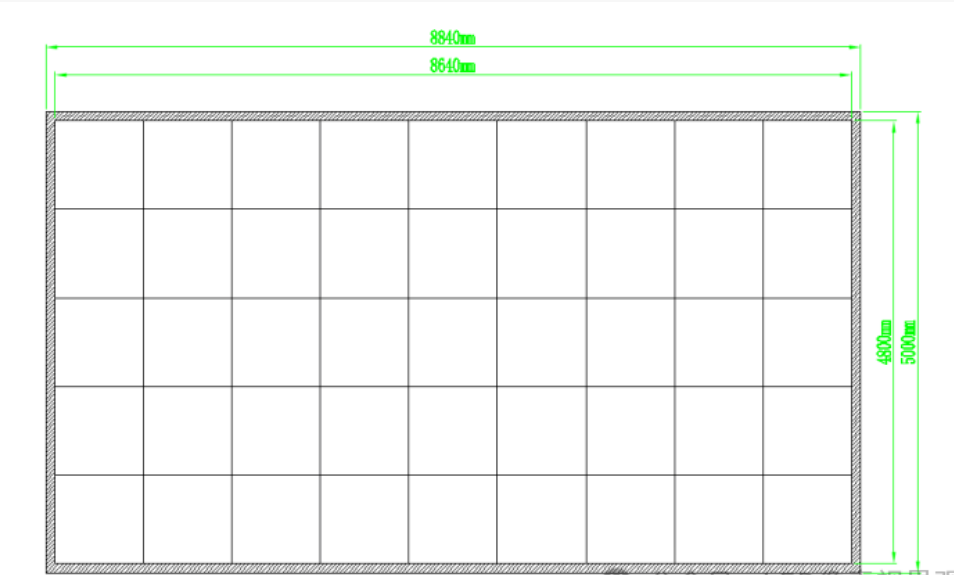

- The net display area measures 8.64m (width, 9 unit cabinets) × 4.8m (height, 5 unit cabinets), totaling approximately 41.47㎡.

- The 16:9 aspect ratio aligns with human visual preferences. It can create an immersive experience for all spectators. With a resolution of 2160×1200 pixels, the display delivers a total of 2.592 million pixel. It is enough to showcase UHD content with stunning detail.

Key specifications at a glance:

- Overall display dimensions: 8640mm × 4800mm

- Unit cabinet size: 960mm × 960mm

- Total unit cabinets: 9×5=45

- Net display area: 41.47㎡

- Resolution: 2160×1200 pixels

Configuration List:

| Serial Number | Equipment Name | Equipment Model/Description | Unit | Quantity | Remarks |

|---|---|---|---|---|---|

| 1 | LED Display Screen | 1. Display type: SMD surface-mount three-in-one, 1R1G1B; Pixel pitch: 4.0mm, pixel density 62500 points/m²; 2. Waterproof sheet metal cabinet, module gap ≤0.1mm; 3. Net display area of a single screen is approximately 41.47 square meters (8.64m wide, 4.8m high), resolution: ≥2160*1200, with a positive deviation range not exceeding 1%, outdoor fixed installation; 4. Display brightness uniformity ≥98%, contrast ratio 8000:1; 5. Display brightness after calibration or white balance brightness ≥5000nit, brightness adjustable from 0-100%; 6. Viewing angle: horizontal and vertical angles ≥165°; 7. Refresh rate ≥1920HZ; 8. Frame rate: 50/60HZ; 9. Mean Time Between Failures (MTBF) interval not less than 100000 hours, Mean Time To Repair (MTTR) time ≤5 minutes; 10. LED display screen and its accessories pass national fire-retardant test standards such as GB/T 5169.5-2008 and GB8624-2012; | m² | 41.47 | |

| 2 | Video Controller | 1. High-bandwidth digital content protection technology with HDCP1.4 protocol, supports 1920*1200@60Hz resolution input, supports arbitrary resolution settings; 2. Supports seamless switching between multiple signals, maximum load of 7.8 million pixels, maximum width of 8192 points, or maximum height of 4096 points; 3. Supports 1 DVI input and 3 HDMI1.4 inputs, supports 12 Gigabit Ethernet port outputs, supports standalone or dual-unit redundancy backup; 4. 3-screen display, window position and size can be freely adjusted, video sources can be switched, cropped, spliced, and scaled arbitrarily; 5. Supports brightness and color temperature adjustment, supports contrast, hue, and saturation adjustment, low brightness with high grayscale, effectively maintaining complete grayscale display at low brightness; 6. Supports RS232 serial port protocol control, dual USB2.0 high-speed communication interfaces for computer debugging and arbitrary cascading between master controllers; | Set | 1 | |

| 3 | Control Software | Dedicated control software, supports unified brightness adjustment of the full screen, hardware working status monitoring, configuration file readback, optional support for unit cabinet temperature monitoring, power supply voltage detection, etc. | Set | 1 | |

| 4 | Intelligent Power Distribution Box | Protection functions: 50KW, with anti-static and lightning protection functions, with power overvoltage, overcurrent, power failure protection, and distributed power-on measures | Unit | 1 | |

| 6 | Steel Structure, Edge Wrapping, Installation, Debugging, and Training | Fixed-structure display screen, designed according to customer requirements | m² | 41.47 | |

| 7 | Air Conditioner | Cooling capacity of 3 horsepower | Unit | 3 | |

| 8 | Axial Flow Fan | Includes fan cover net | Unit | 4 | |

| Cables and Supporting Accessories | Cables for large screen | Item | 1 |

Core Product Selection:

We’ve handpicked each component to ensure the display performs flawlessly in stadium environments.

Energy Efficiency:

Our high-end energy-saving LED display reduces power consumption by over 50% without sacrificing brightness or image quality. How? We’ve integrated multiple innovative technologies:

- A next-generation control system with intelligent PWM drive technology maintains color consistency even as brightness adjusts. It can cut energy use while stabilizing performance.

- Automatic brightness adjustment syncs with ambient light. It can eliminate wasted energy during dawn, dusk, or night games.

- Optimized PCB board design shortens circuit paths and widens power cables, reducing energy loss.

- High-brightness Nationstar LED chips have improved viewing angles and require 40% less drive current than traditional chips at the same brightness.

- Low-voltage power supply (4.0-4.2V instead of 5V) minimizes energy waste from voltage drops.

Internal heat isolation in cabinets separates power and LED driver heat.

The result? A LED display is environmentally friendly, cost-effective to operate.

Superior Weather Resistance:

Our outdoor displays meet IP65 waterproof and dustproof standards. Moreover, it has 3mm full silicone potting on module frontages and anti-moisture conformal coating on circuit boards.

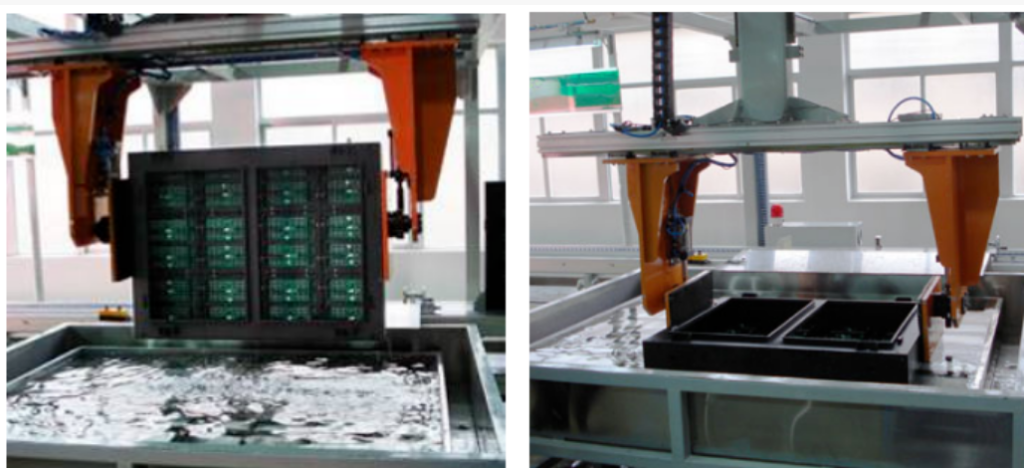

Every unit undergoes rigorous immersion testing before shipment. We also subject displays to extreme environmental testing. through high temperatures (+85°C), low temperatures (-25°C), high humidity (98%), and low humidity (5%) to guarantee reliability in even the most unpredictable conditions.

High Contrast:

Our display has a contrast ratio of no less than 1000:1. This level of contrast brings out the richness of team colors, the sharpness of text, and the depth of video content. It can keep audiences engaged from every seat.

High Grayscale:

14-16bit grayscale processing delivers a palette of millions of colors. So, it will create lifelike, three-dimensional visuals that avoid the flat, distorted look of lower-grayscale displays.

Our high-end control system supports 12bit signal input and 16bit output, while S-PWM drive technology maintains grayscale quality even at low brightness. It can eliminate flicker and ensure consistent color accuracy.

Uniform Brightness:

Poor brightness uniformity creates distracting “mosaic” patterns. Our displays undergo strict brightness calibration during production.

Stable Signal Transmission:

Our proven transmission system delivers strong, stable signals over long distances. It tested and validated in over five projects with displays exceeding 1000㎡.

Consistent Appearance:

Mismatched module masks create unsightly color variations. We subject every mask to strict ink color sorting before shipment.

Rigorous Stability Testing

Dead or flickering pixels detract from professionalism. Our displays undergo extreme temperature shock, high humidity, and vibration testing,resulting in near-zero dead pixels.

Control System:

To unlock the display’s full potential, we’ve selected the JZ-X12 dual-function video processor:

Versatile Input/Output: Supports 3 HDMI 1.4 ports and 1 DVI port, adapting to diverse video sources. With 12 network output ports and a maximum load of 7.8 million pixels, it handles ultra-large displays with ease.

Stunning Image Quality: HDR support enhances color gamut and contrast.

User-Friendly Operation: Save custom scene templates for quick recall, with intuitive software control and smart screen configuration tools.

Advanced Image Processing: Handles 1920×1200@60Hz UHD content, with features like image scaling, low latency, and pixel-level brightness/color calibration for flawless playback.

Redundant Backup: Supports single or dual-machine redundancy.

Steel Structure:

The display’s mounting structure can be withstand 12-level winds and 7-level earthquakes. It use national standard steel with precision welding for maximum stability.

Power Distribution System:

Our custom XL-50 power distribution cabinet (50Kw capacity) is strategically placed around the display. Cables between the power room and cabinets use national standard 5-core unarmored cables (minimum specification: 4×25mm²+1×16mm²).

Our Stadium Outdoor LED display Reliability Technology Solutions:

To ensure our LED display operates flawlessly for years, we’ve integrated a suite of industry-leading protection technologies.

Dust, Moisture, and Corrosion Protection:

LED display PCB survival depends on robust protection against dust, moisture, and corrosion. We adhere to high-grade electronic equipment standards for all exposed parts, implementing two critical safeguards:

High-Grade Protective Coating

Our PCBs are coated with a high grade-formulated protective fluid that does far more than repel moisture. It forms a formidable barrier against corrosion and dust. This advanced coating creates a thin, flexible film (25-50 microns thick) that adheres tightly to circuit surfaces, shielding them from harsh environmental threats.

Imported Anti-Oxidation Solder Paste

To complement the protective coating, we use imported anti-oxidation solder paste for all board assembly, paired with a green oil oxygen barrier on PCBs. Every step of the production process from component insertion and soldering to cleaning, drying, and protective coating application. It is executed by professional automated equipment.

World-Class Waterproof Design:

Water damage is the single greatest threat to outdoor electronics. Our waterproof design isn’t just an afterthought; it’s a core feature built into every module and cabinet.

Custom Silicone Gaskets: Every display module is fitted with acid and alkali-resistant gaskets made from imported silicone rubber.

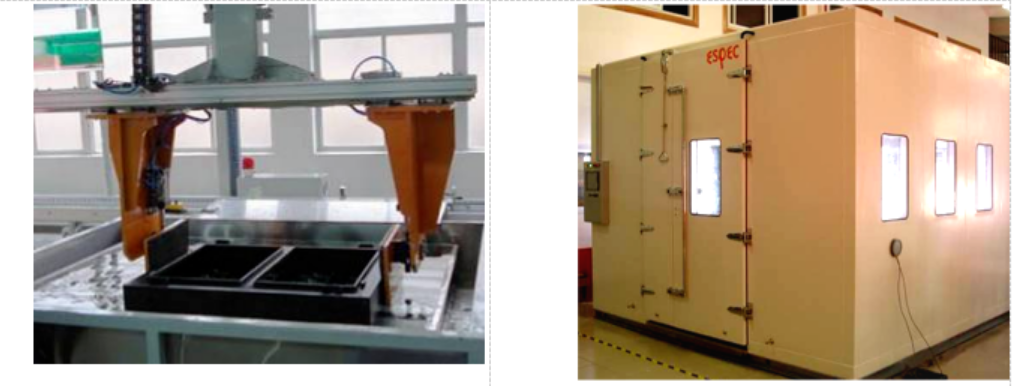

Immersion Testing for IP65 Certification: Unlike traditional manual spray or shower tests, our production facility uses specialized immersion testing equipment. Each cabinet undergoes targeted, timed, and pressure-controlled immersion testing to verify IP65 waterproof performance.

UV Resistance:

Prolonged exposure to ultraviolet (UV) radiation fades materials, weakens structures, and shortens component lifespans. Our display combats this with a specialized UV-resistant design:

We use high-performance polycarbonate (PC) blended with high-strength glass fiber and flame retardants, enhanced with UV-stabilizing additives.

Anti-Deformation Module Housing:

Local temperature fluctuations from scorching highs to freezing lows. It can warp unreinforced structures over time. Our module housings are used to resist deformation and cracking, even in extreme conditions:

Using proprietary patented molds, we’ve integrated a grid-like reinforcing rib structure into all structural components.

Comprehensive Waterproof Treatments:

Beyond cabinet-level waterproofing, we’ve implemented multiple layered defenses to ensure absolute water resistance:

Module Potting with High-Quality Silicone: Each display module is fully potted with premium organic silicone, which offers exceptional flow properties for complex electronic components. Once cured, it forms a flexible rubber-like barrier that absorbs impact, resists heat, moisture, and cold, and extends component life. The silicone is condensation-curing, releasing ethanol molecules that won’t corrode sensitive components, and requires no primer.

IP65 Module Testing:

Every unit module undergoes a dedicated 3-minute IP65 waterproof test to validate its seal integrity.

Fully Sealed Cabinets:

The entire cabinet is hermetically sealed,which provides protection against rain, dust, moisture, and salt spray in all weather conditions.

Dust Prevention:

Dust accumulation can clog vents, scratch surfaces, and degrade performance over time.

Front-Face Dust Resistance: The display’s front surface features an advanced anti-dust accumulation design.

Silicone Sealing: The front surface is sealed with silicone, maintaining dust and water resistance for up to 10 years.

Rear Ventilation with Dust Screens:

The cabinet’s rear uses a channeled ventilation system, drawing air from the bottom of the back door. A fine dust screen at the air intake blocks debris from entering the cabinet while maintaining airflow for heat dissipation.

Sun Protection:

Direct sunlight doesn’t just affect visibility. It elevates internal temperatures, accelerating LED degradation. Our sun protection design targets both the display’s optics and components:

Optical Simulation for Mask Design:

We use LED display optical simulation software to optimize the LED mask. By analyzing sunlight exposure angles , we adjust the spacing between LEDs and the mask to find the optimal position.

High-Temperature Rated Components:

LEDs, power supplies, and driver ICs all meet industrial-grade standards, capable of operating at temperatures exceeding 80°C.

Anti-Glare Treatment:

Glare from sunlight can wash out images and strain viewers’ eyes. Our anti-glare design solves this while protecting internal components:

Matte Finish with Unique Texturing:

The display surface uses a matte material with an exclusive textured pattern, minimizing light reflection to boost contrast and improve image clarity.

Component Protection:

By reducing direct sunlight on LEDs, the anti-glare design slows LED aging and extends their service life. It also shields waterproof silicone from UV damage, maintaining its waterproof performance over time.

Conclusion:

This outdoor LED display project design isn’t just about installing a screen. By combining energy efficiency, rugged durability, and cutting-edge technology, we’ve created a solution that meets the unique demands of stadiums.

At SightLED, we don’t just supply displays. From initial design to post-sales support, our team works with you to tailor every detail to your stadium’s needs. With over 5,000 successful installations worldwide and a focus on high-grade quality, you can trust our solution to enhance your display project. Ready to take your stadium to the next level? Let’s bring this vision to life together.