What is the Stadium LED Displays?

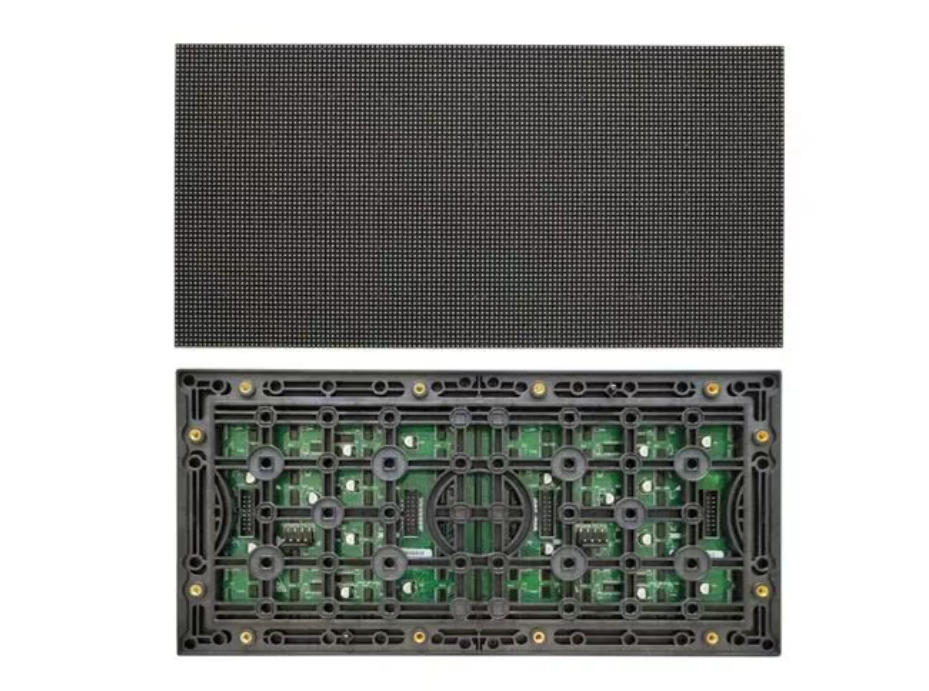

Stadium LED displays are large electronic screens or panels that are installed in sports stadiums and arenas to provide visual content and information to the spectators. These displays use light-emitting diode (LED) technology to produce high-resolution and vibrant visuals that can be easily seen from a distance, even in bright daylight.

Stadium LED displays are commonly used to showcase live video feeds of the game, replays, player statistics, and scores. They can also display advertisements, sponsor messages, and other promotional content. Additionally, these displays can enhance the overall fan experience by showing interactive content, fan engagement activities, and entertainment elements during breaks in the game.

Stadium LED screens are designed to be durable and weather-resistant, capable of withstanding the outdoor elements and the physical impact of sports events. They come in various sizes and shapes, ranging from small scoreboards to massive video walls that span across multiple sections of the stadium.

What should you pay attention to when using LED displays?

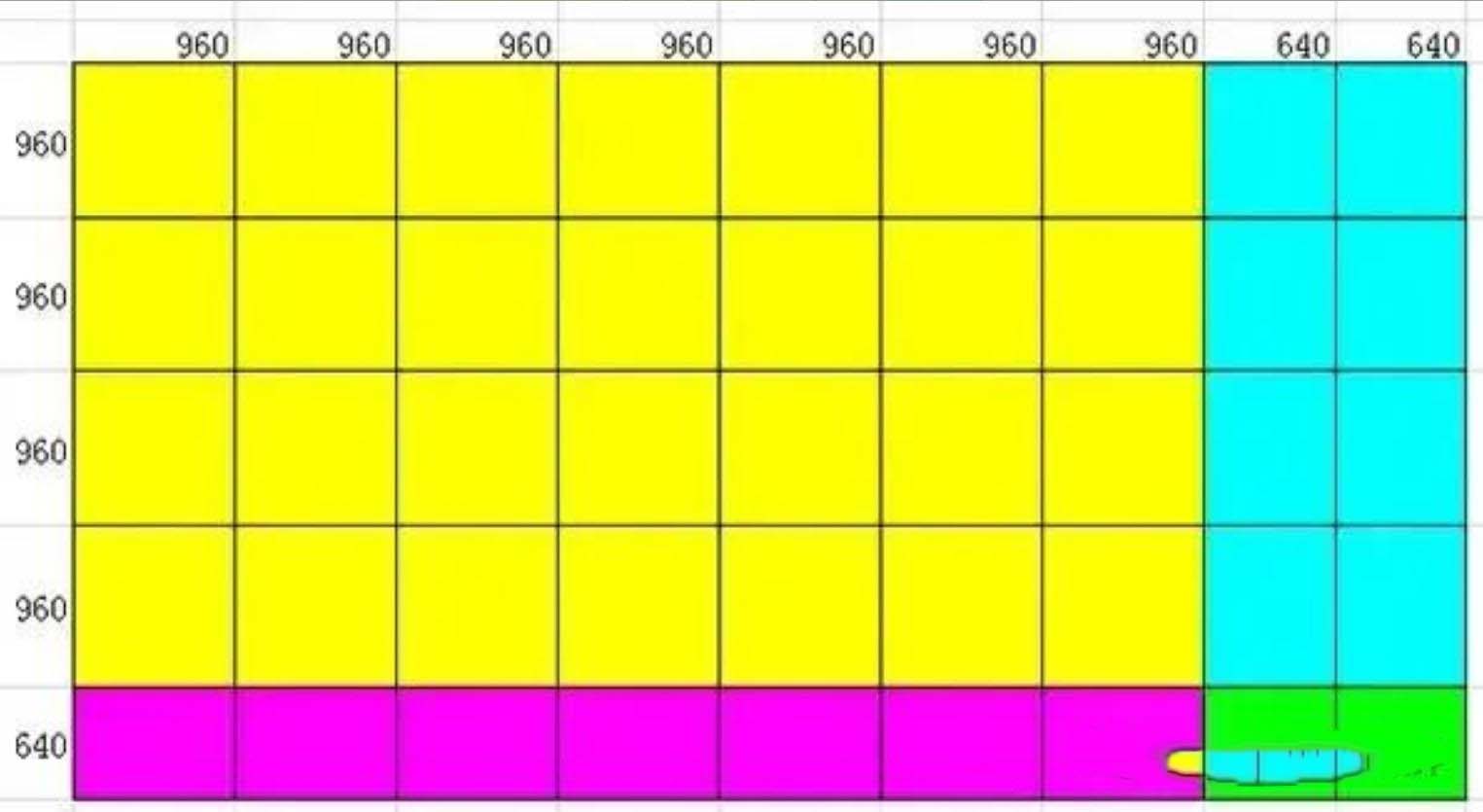

LED displays currently attach great importance to the details of the screen, and have very high requirements for the details of each project. Seamless splicing technology is constantly improving, and their display effects ensure the perfection of the final display effect.

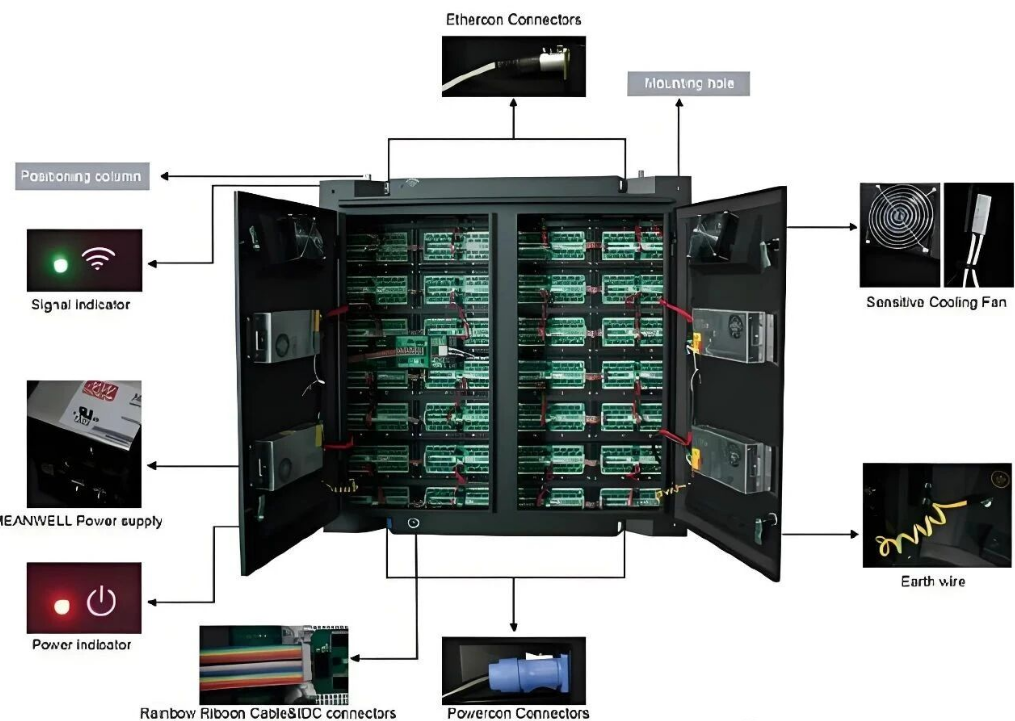

From the perspective of the process of using LED displays, dust protection is also a very important part of the process. How to achieve better dust prevention is a very important aspect of the upgrade of LED display technology.

There are many optical components in the LED display screen. During our use, there will be a lot of dust in the air, which will then enter the inside of the machine through some small gaps, thus affecting the normal operation of the entire screen light machine. The optical components are vulnerable to dust. We cannot underestimate the harm of dust to optical components. Sometimes a small amount of dust can cause fatal damage to our machines.

Too much dust will reduce the brightness of our screen. If the LED display is installed in a dusty environment, generally if there is too much dust, the brightness will be reduced by 30%. In severe cases, the brightness of the screen may be reduced. It is reduced by 70%, so we must find ways to make our system less dusty during operation. If there is dust, we must remove it as soon as possible through the correct method.

The effect of dust appearing on the color wheel, as shown in the screen display, is that the color wheel generates 7200 RPM during operation. Accumulating a large amount of dust will cause the color wheel to rotate unevenly, causing the image to display color shifts.

Precisely because dust has such a great impact on our entire large screen system, we must pay special attention to the operating environment of the LED display.

Below I have summarized the precautions for LED screen switch and software operation.

1. LED display switch precautions

(1) Power on and off sequence: When turning on the screen, turn on the phone first and then turn on the screen; when turning off the screen, turn off the screen first and then turn off the phone. If you turn off the computer first without turning off the display screen, it will cause high spots on the screen and burn the tube, with serious consequences.

(2) When opening and closing the screen, the interval should be greater than 5 minutes.

(3) After the computer enters the engineering control software, the screen can be turned on and powered on.

(4) Avoid opening the screen in the full yellow state, because the inrush current of the system is the largest at this time.

(5) Avoid opening the screen in the following three out-of-control states, because the system’s inrush current is the largest at this time. ① The computer does not enter programs such as engineering control software. ②The computer is not powered on. ③The power supply of the control part is not turned on.

(6) The computer system shell is charged and the screen cannot be turned on.

(7) When the ambient temperature is too high or the heat dissipation conditions are not good, be careful not to leave the screen open for a long time.

(8) When a part of the display screen appears with a very bright line, you should turn off the screen in time. It is not advisable to keep the screen on for a long time in this state.

(9) When it is confirmed that the power switch of the display screen is tripped frequently, the screen body should be checked or the power switch should be replaced in time.

(10) Regularly check the firmness of the screen mounting points. If there is any looseness, make timely adjustments. If necessary, re-reinforce or replace the hanging parts.

(11) Observe the environmental conditions of the display screen and the control part. The screen should be prevented from being bitten by insects. Anti-rodent pesticides should be placed if necessary.

2. LED display software operation precautions

(1) Applications, software installation programs, databases and other software should be backed up.

(2) Be proficient in installation methods, original data recovery, and backup levels.

(3) Master the setting of control parameters and the modification of basic data presets.

(4) Proficient in using, operating and editing programs.

(5) Regularly check for viruses and delete irrelevant data.

(6) The LED display screen should be managed by full-time personnel; non-full-time personnel cannot operate the software system.

Not only the LED display industry, but also in various production sectors in the social field and even in the public management of society, the order of innovation is a very important factor. Only by insisting on innovation and putting forward new developments in products and technologies will it be possible to make enterprises and industry to achieve long-term progress and development.