In the design of LED display circuit boards, the LED modules and driver boards are the key components. Currently, there are two common design approaches in the market: LED Screen integrated driver and LED separate driver. If you are selecting the right LED display, you had better know these two design schemes . This article will provide a detailed explanation.

Table of Contents

ToggleWhat is the LED Dislay Integrated Driver Design?

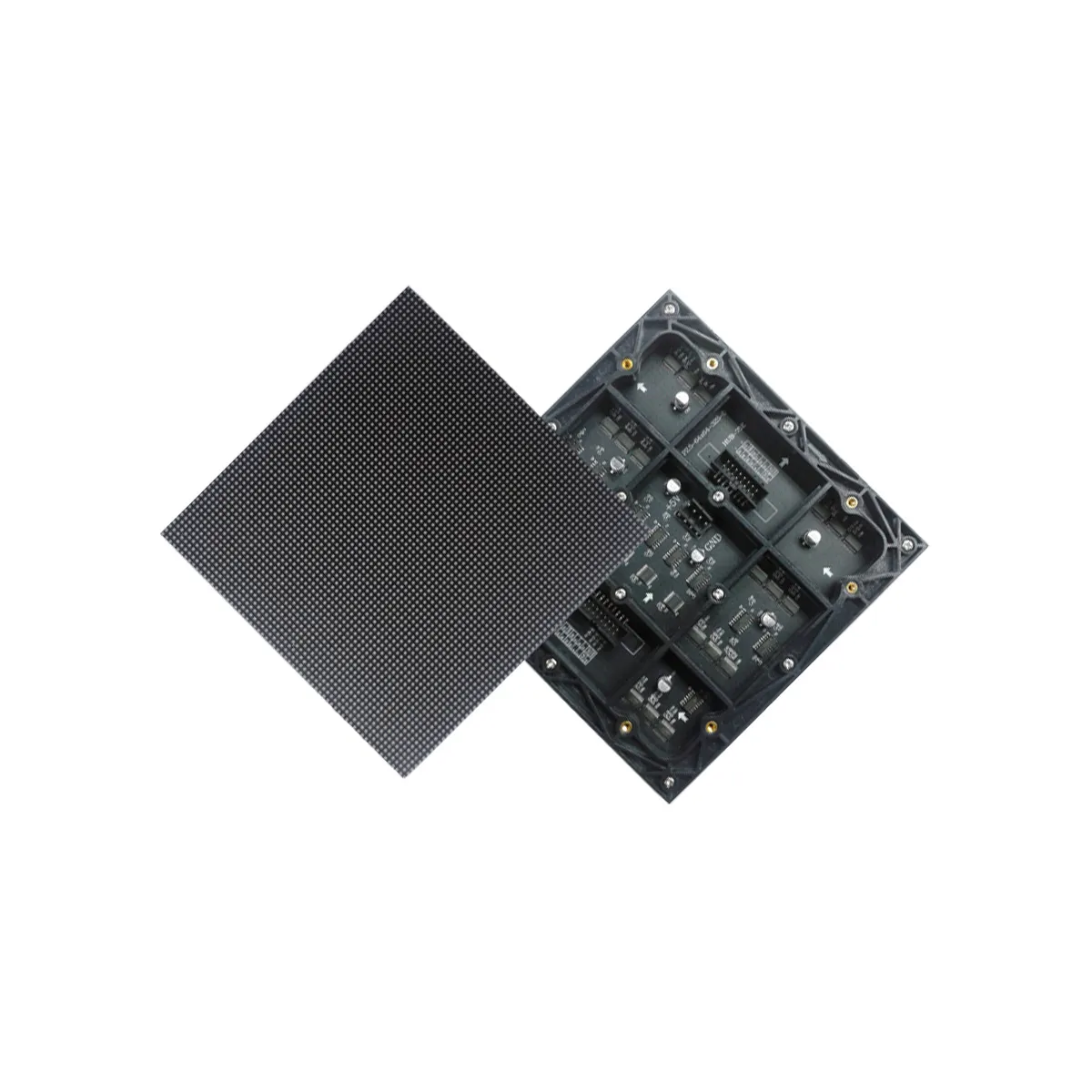

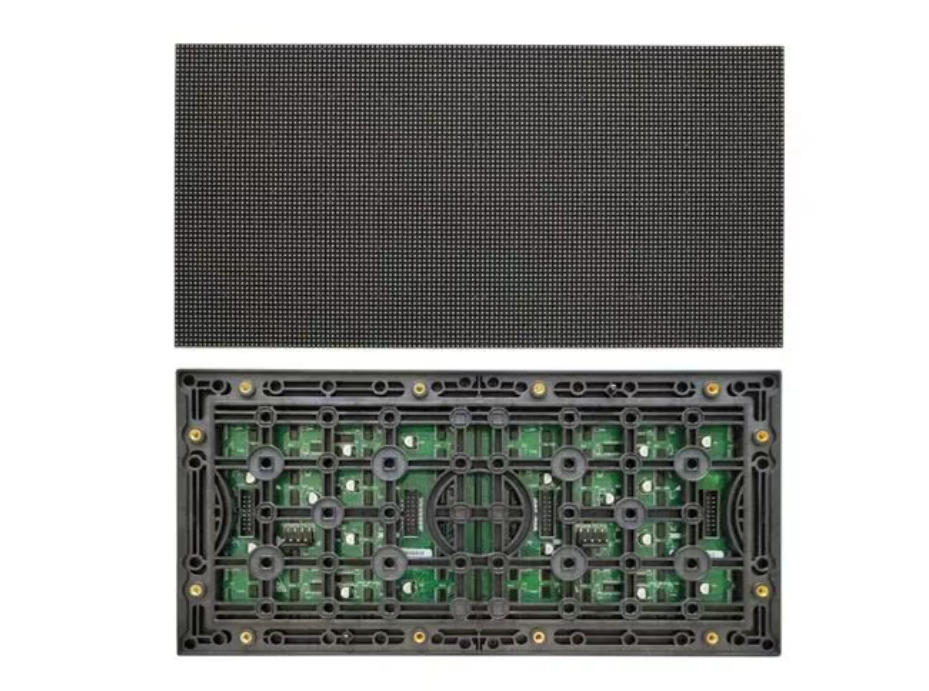

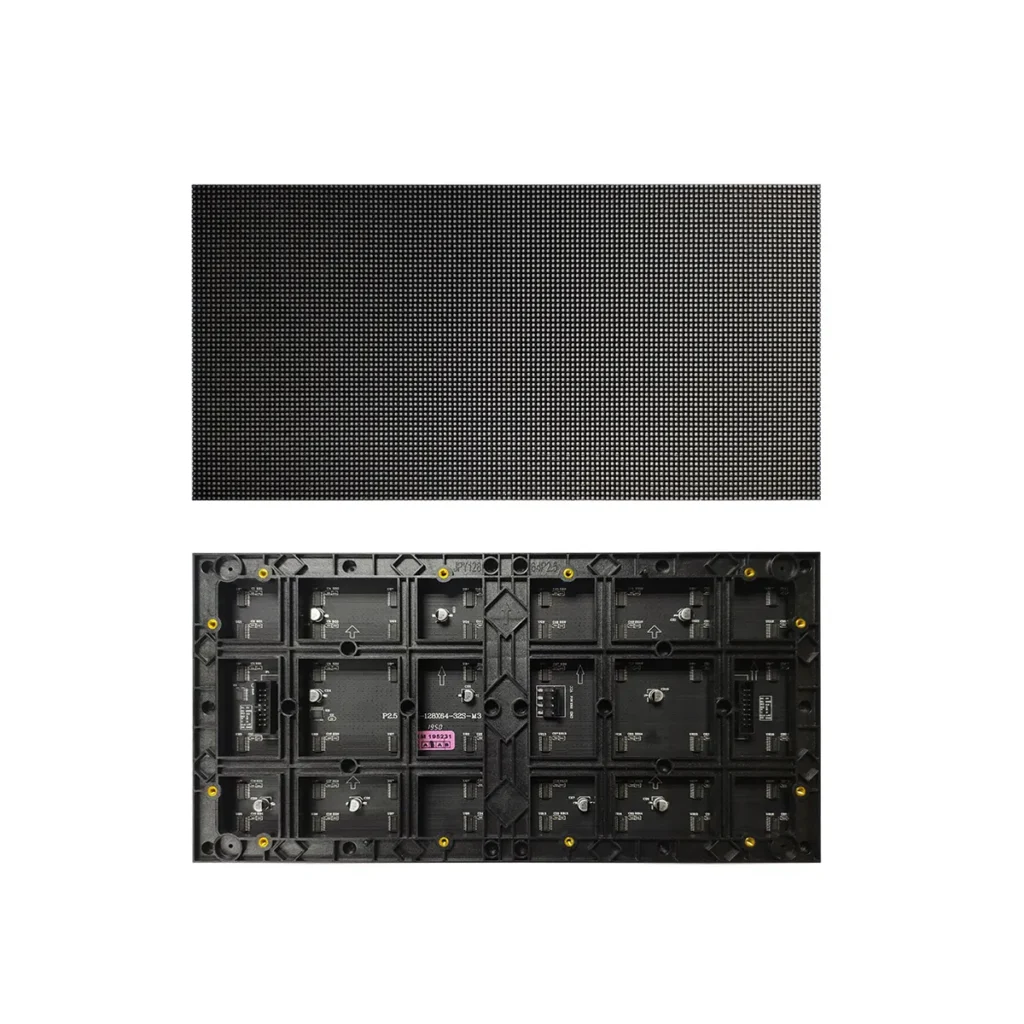

The integrated driver design refers to a setup where the LED light source and the driver IC are placed on the same PCB board. In this design, the LED lights and the driving chips are integrated into a single compact unit. The ICs are typically positioned on the front of the PCB, eliminating the need for copper bar connectors.

Advantages and Disadvantages of Integrated Driver Design

Advantages:

1. Simplified Design: The high level of integration makes the design more compact.

2. Lower Cost: The integration of components reduces the need for extra connectors and complex wiring, making it cost-effective.

3. No Inductive Effect: Since there are no external connectors, the design avoids issues like inductive effects that could cause display flickering or glitches.

Disadvantages:

1. Difficult Maintenance: If the driver IC fails, the entire PCB may need to be replaced or repaired, Therefore,its maintenance is more complicated.

2. Heat Dissipation Issues: The integrated driver IC generates heat that may affect the LED’s performance, particularly in high-density screens.

What is the LED Screen Separate Driver Design?

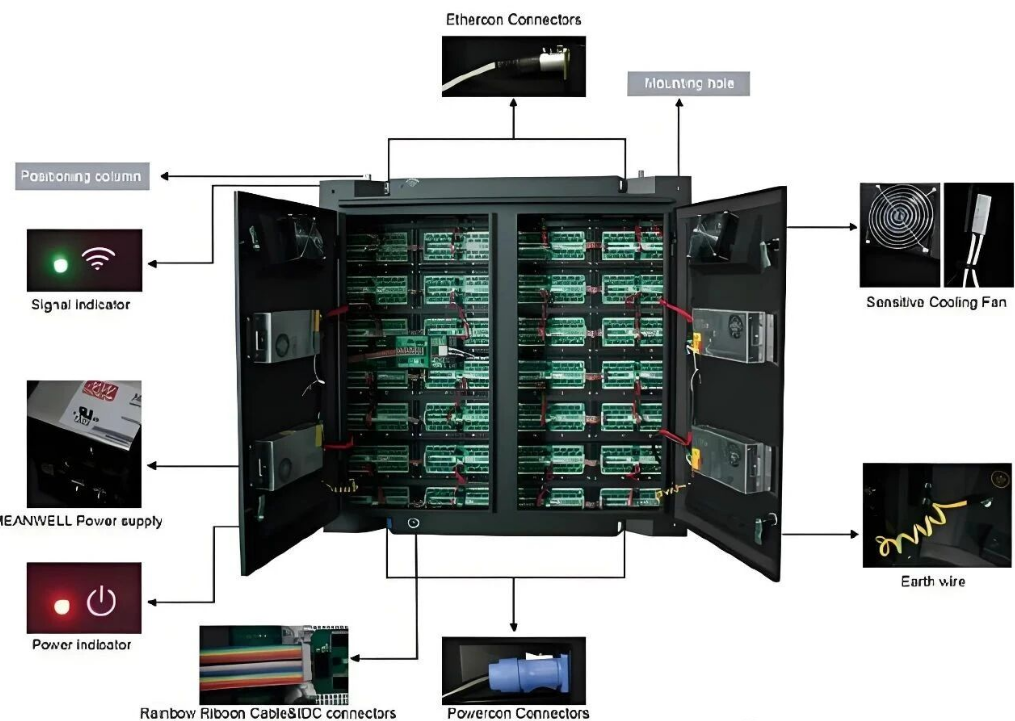

In contrast, the separate driver design places the LED light source and the driver IC on separate PCB boards. These two boards are connected through pins or connectors, allowing for signal transmission and proper operation.

Advantages and Disadvantages of Separate Driver Design

Advantages:

1. Better Heat Dissipation: With the driver IC separated from the LED lights, the heat generated by the IC doesn’t directly affect the LED’s performance. For high-density LED screens,it have more advantages.

2. Easier Maintenance: If either the driver IC or the LED module fails, only the faulty part needs to be replaced. You can easily and more cost-effective to repair them.

3. More Flexible Design: The LED and driver IC can be placed optimally, allowing for better routing of PCB tracks and larger design flexibility.

Disadvantages:

1. Higher Cost: The need for two separate PCBs increases the manufacturing cost.

2. More Complex Design: The design complexity increases due to the need for additional connectors and signal routing.

Why is Separate Driver Design More Commonly Used?

Although the integrated driver design offers some cost benefits, the advantages of the separate driver design make it the preferred choice in many applications. Here are some of the main reasons:

Impact of Through-hole LEDs on Driver IC Placement

Many outdoor LED displays use DIP LEDs (soldered into the board), and the legs of these LEDs can obstruct the proper placement of the driver IC. To overcome this issue, the separate driver design is often used, as it allows the LED and driver IC to be positioned independently.

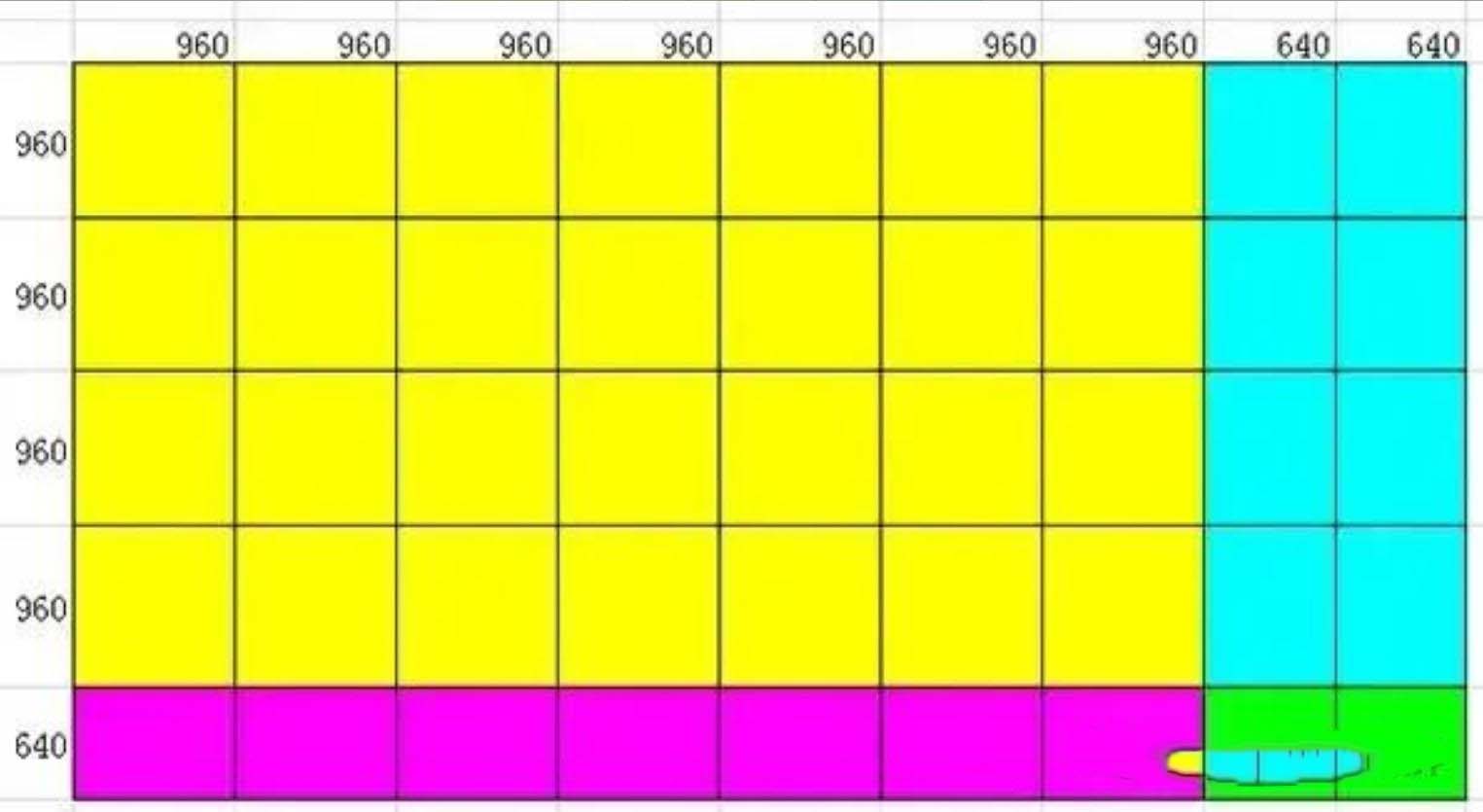

Small Pitch LED Screens and Routing Needs

For small-pitch screens (e.g., P2.5, P1.9), they have very tight pixel pitch. This tight spacing can affect the routing of PCB traces. The separate driver design provides more flexibility in PCB design, it can offer larger routing areas and optimal layout.

Improved Heat Management

In high-density LED displays, the driver IC can generate significant heat. In an integrated driver design, this heat may directly affect the LED modules, leading to color shifts or even failure. With separate driver designs, the IC and LEDs are separated, It can ensure better thermal management and more stable display performance.

Comparing Integrated vs. Separate Driver Designs

Let us quickly know these differences between these. It can help determine the best solution for specific needs. Here’s a comparison of the integrated and separate driver designs:

Cost Comparison

The integrated driver design is more cost-effective. By integrating both the LED and driver IC on the same PCB, the overall cost of production is lower.

Maintenance Comparison

The separate driver design is easier to maintain. Because the LED modules and driver ICs are separate, it is easier to identify and replace faulty components. If the driver IC fails, only the driver board needs replacement, while the LED board remains intact.

Heat Dissipation Comparison

The separate driver design offers better heat dissipation. Since the driver IC is placed away from the LED light source, the heat generated by the IC will not affect the LED’s performance, It can ensure more stable and reliable operation, especially in high-density and outdoor applications.

Application Suitability

Integrated driver designs are typically used in low-density, small-sized indoor displays. Separate driver designs are more common in high-density, large-sized, outdoor displays, where heat management, display stability, and ease of maintenance are more important.

When to Use Integrated Driver vs. Separate Driver Design?

The choice between integrated driver and separate driver designs largely depends on the application requirements and the environment.

Indoor LED Displays

For low-density, small-pitch indoor displays, the integrated driver design is often chosen. The lower cost and simpler design are beneficial for applications where the display does not need to operate in extreme conditions or for long periods.

Outdoor LED Displays

For outdoor LED displays, especially those with small pixel pitches, the separate driver design is generally preferred. These displays need to operate in more demanding environments. They often need high brightness and extended operating hours, and good heat dissipation and durability.

Summary

In terms of integrated driver and separate driver designs LED diaplay, each have their own strengths and weaknesses. The integrated driver design is cost-effective and simple but has limitations in terms of heat dissipation and maintenance. However, the separate driver design LED screen offers better heat management, easier maintenance, and greater design flexibility, but at a higher cost.

In general, for HD indoor displays, the integrated driver design may be sufficient. However, for high-density, outdoor displays, the separate driver design is the better choice. We have guide you both designs, you can make a more informed decision based on the specific requirements of your LED display application. If you are looking for LED screens and still don’t know how to choose, please feel free to contact us, our experts will give you the best solution.