In recent years, GOB packaging technology has taken the LED industry by storm. It’s not just a new technical trend. This innovation brings many benefits to LED products across diverse applications.

But here’s the question many industry professionals ask: When should you choose GOB packaging for your creative LED projects? Today, we will guide you the details.

Table of Contents

ToggleWhat Is GOB Technology?

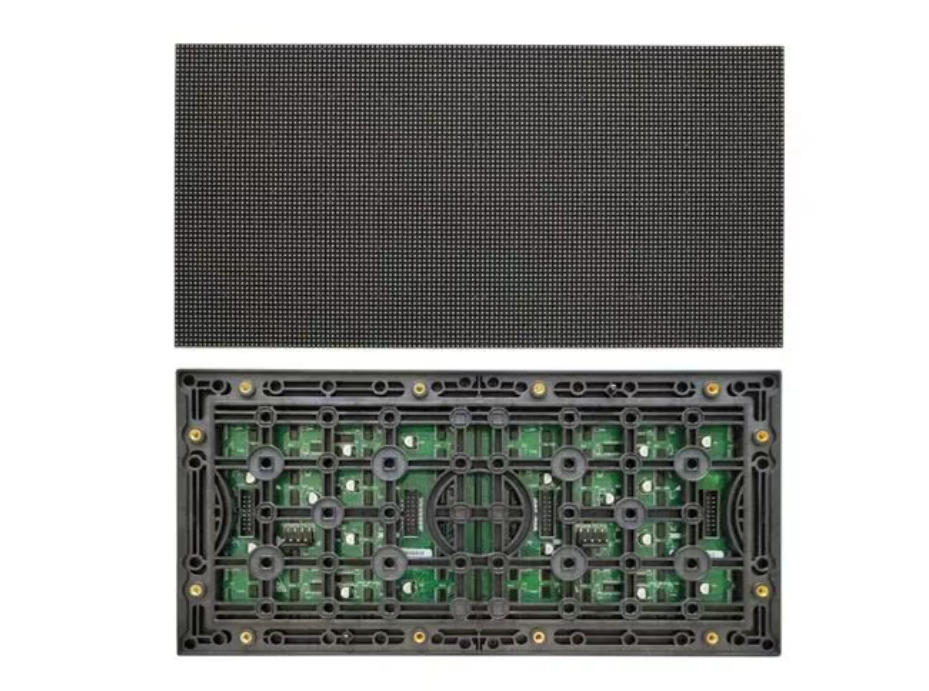

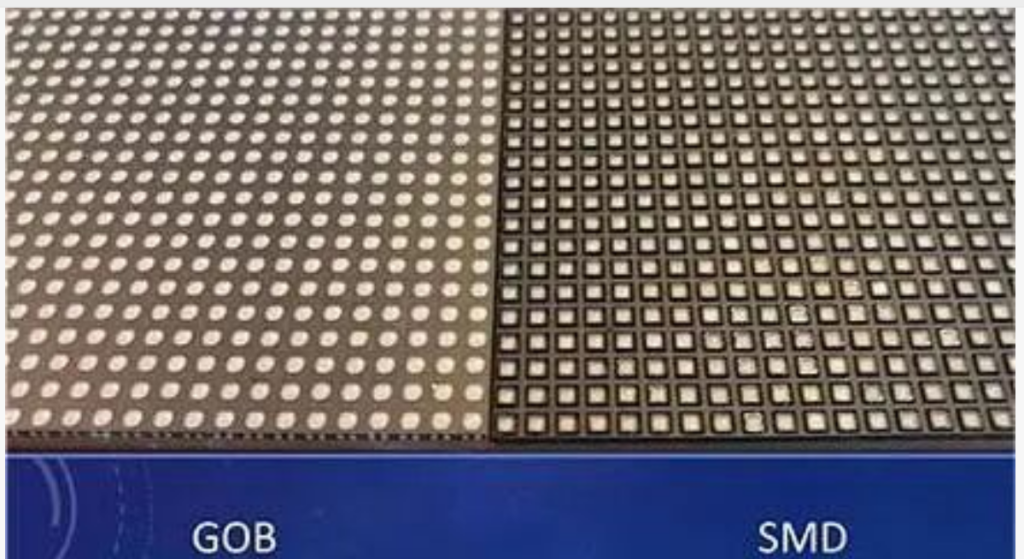

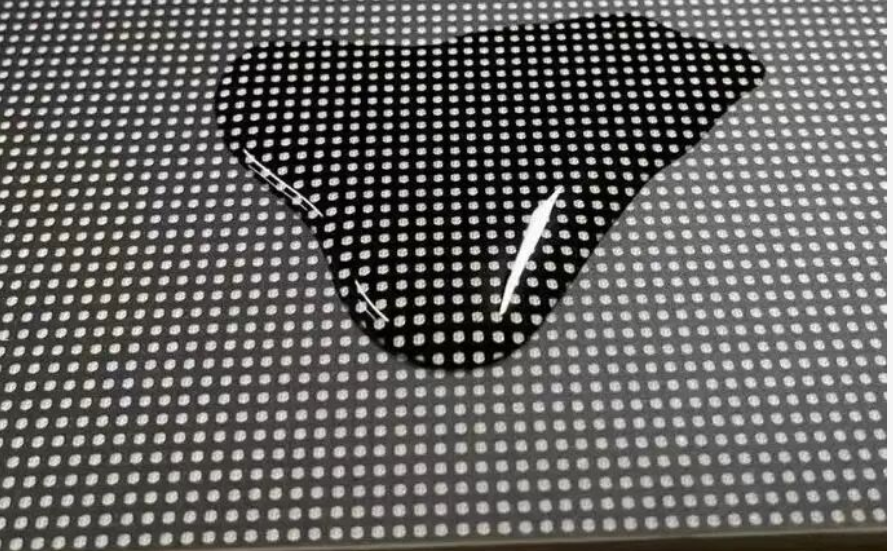

Let’s start with the basics. GOB stands for “Glue On The Board,” and as the name suggests, it’s a packaging technology that uses a special optical thermally conductive nano-filler material. Through a proprietary process, we apply this material to the PCB board of a standard LED display. It can fully cover the SMD LED chips. The result? It doesn’t just enhance protection, it also revolutionizes the display’s visual performance.

Unlike traditional LED screens, which leave their light-emitting components fully exposed, GOB technology wraps the entire PCB and LEDs in a protective, light-diffusing layer. Therefore, it address the long-standing pain points in the industry.

You’ll often see two common GOB configurations:

- Edge-wrapped

- Non-edge-wrapped .

Both leverage the same core material and process but differ in whether the protective glue extends to the screen’s edges.

GOB Solves Critical Industry Pain Points

Traditional exposed LED screens have fatal flaws, so it is limit their use in creative or harsh environments. GOB technology directly targets these issues, making it more reliability and longevity:

Low Protection Level:

Traditional LED screens struggle with moisture, dust, shocks, collisions, and static electricity. In humid climates, they frequently suffer from dead LEDs or broken circuits. During transportation or installation, loose LED chips are common, leading to costly repairs. Static electricity also causes unexpected dead lights, ruining the display’s uniformity.

Thanks to GOB’s fully encapsulated design, it can eliminate these risks. The nano-filler glue acts as a barrier, sealing out moisture, dust, and debris. It also absorbs shocks and prevents chip damage during handling. For creative displays, like stage backdrops or temporary art installations or long-term outdoor use, this protection is non-negotiable.

Reduced Eye Strain and Blue Light Harm

Another major flaw of traditional LED screens is their harsh light output. Long-term viewing causes glare, eye fatigue, and even “blue light damage.” Blue LEDs emit short-wavelength, high-frequency light that can damage the retina with prolonged direct exposure.

GOB’s frosted surface diffuses light evenly, eliminating glare and softening the visual experience. It also filters harmful blue light, reducing eye strain significantly. Therefore, GOB LED display is ideal for indoor creative displays, like art galleries, shopping malls, or corporate lobbies,

Core Advantages of GOB Technology

Beyond solving industry pain points, GOB offers several benefits:

The “8 Protections” Advantage

GOB’s most celebrated feature is its comprehensive protection:

- waterproof

- moisture-proof

- collision-proof

- dust-proof

- corrosion-proof

- blue light-proof

- salt-proof

- anti-static.

This “8 protections” package makes GOB screens versatile enough for almost any environment.

Enhanced Visual Performance

The frosted surface isn’t just for protection, it also improves image quality. By converting point light sources to surface light sources, GOB increases color contrast and expands the viewing angle. Traditional LED screens often suffer from color distortion when viewed off-center, but GOB maintains consistent brightness and color from almost any angle.

Space-Saving and Efficient Production

GOB simplifies the packaging process by integrating the protective layer directly onto the PCB. It eliminates the need for additional casings or frames. Therefore, GOB screens can be thinner and lighter. It is perfect for creative projects with tight installation constraints ,like ceiling-mounted displays or thin creative walls.

It also streamlines mass production, improving efficiency and reducing costs for large-scale creative installations.

Effective Thermal Management

The nano-filler material in GOB designs has excellent thermal conductivity. It dissipates heat generated by LED chips evenly across the PCB. It can prevent overheating and extend the display’s lifespan. For high-density creative displays, effective thermal management ensures stable performance and avoids premature failure.

GOB’s Production Process

GOB’s reliability doesn’t happen by accident. It requires a rigorous six-step production process, paired with automated equipment, custom molds, and specialized packaging materials.

Material Selection:

GOB relies on custom-formulated packaging glue. It is developed specifically for LED display applications. This glue must meet 10 strict criteria: strong adhesion to PCB and LEDs, high tensile and vertical impact strength, appropriate hardness, high transparency, temperature resistance, yellowing resistance, salt spray resistance, high wear resistance, anti-static properties, and high-voltage resistance. Cutting corners on glue quality ruins the entire GOB advantage, so reputable LED display manufacturers ,like SightLED never compromise here.

Filling:

The filling process requires the glue to fully fill the gaps between LED chips and cover the entire chip surface, adhering tightly to the PCB. There’s no room for defects: bubbles, pinholes, white spots, gaps, or incomplete bottom filling all lead to performance issues. Automated filling equipment ensures precision, ensuring every part of the PCB is evenly covered.

Thickness Control:

Consistent glue layer thickness is make-or-break for GOB. Uneven thickness causes a host of problems: modular discoloration, screen flicker, uneven tiling, and poor color consistency in both bright and dark states. Thanks to GOB 4.0 technology, modern production achieves near-zero thickness tolerance.

Leveling:

After filling, the screen undergoes leveling to ensure a smooth surface with no bumps or waves. A uneven surface disrupts light diffusion, ruining the display’s visual uniformity.

Surface Treatment:

Surface treatment varies based on product needs, with three common options: matte , semi-matte, and glossy. Matte is the most popular for creative displays, as it reduces glare and enhances the surface light effect. Glossy may be used for specific reflective art installations, while semi-matte balances glare reduction and brightness.

Maintainability:

A common misconception is that fully encapsulated GOB screens are unrepairable. In reality, GOB glue is used to be easily removed under specific conditions. After repairing faulty components ,like dead LEDs, technicians can refill and re-level the area, restoring the screen to its original condition.

GOB’s Applications: Which LED Displays Benefit Most?

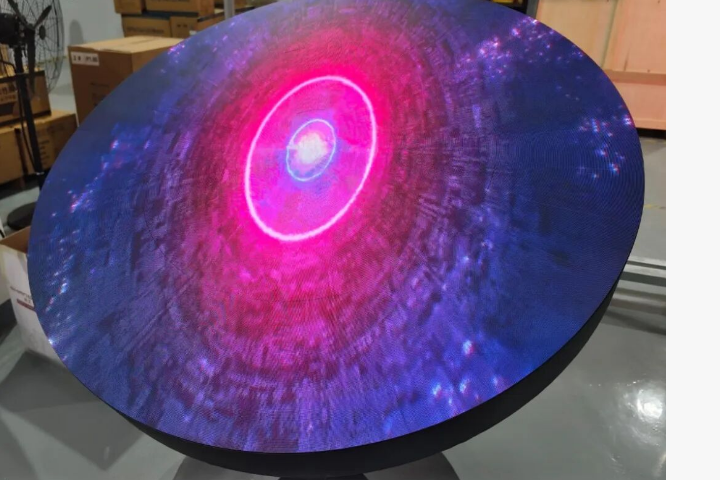

GOB technology isn’t limited to specific screen types. It enhances almost all LED displays, especially creative and high-demand applications:

Compatible LED Screen Types

GOB works with small-pitch LED displays, ultra-protective rental LED screens, ultra-protective floor-standing interactive LED screens, ultra-protective transparent LED screens, LED smart panel displays, LED smart billboards, and LED creative displays.

Expanded Application Scenarios

Thanks to its protection and visual benefits, GOB expands LED’s reach into: stage rental,exhibition displays, creative art installations, advertising media, security monitoring, command centers , transportation hubs, stadiums , broadcasting studios , smart cities , real estate , and special engineering projects .

The Big Question: Should You Choose GOB for Irregular-Shaped or Creative Screens?

For creative display, if you use GOB deppends on three key factors:

Pixel Pitch:

P2.5 or below Small-pitch LED screens benefit most from GOB. These screens have dense LED chips. Therefore, it is more vulnerable to dust, moisture, and static damage. GOB’s protection ensures uniformity and longevity, which is critical for high-resolution creative displays like fine-pitch artworks or detailed stage backdrops. For above P2.5 larger pixel pitches, GOB is still useful for harsh environments, but the need is less urgent.

Project Timeline:

GOB adds extra steps to the production process, so you’ll need to reserve more time for manufacturing. If your project has a tight deadline, GOB’s production lead time is more long. Rushing the GOB process leads to quality issues, so it’s better to plan ahead than compromise on performance.

Environment and Use Case:

If your creative display will be used outdoors, in humid/ corrosive environments, or in high-traffic areas , GOB is a wise investment. It protects against weather, physical damage, and wear and tear. For indoor creative displays , GOB is still beneficial for eye comfort and visual performance, but it may be optional depending on budget.

Related:

The Future of GOB Technology

GOB has already gained widespread adoption and a strong reputation in the LED industry. As technology matures and production costs decrease, it’s poised to become the mainstream packaging method for creative LED displays. By protection, visual performance, and versatility aligns , industry’s shift toward more innovative, durable, and user-friendly displays.

COB Vs. GOB LED Display:How Much Does GOB LED Screen Cost?

Final Thoughts:

GOB packaging technology isn’t just an upgrade. it’s a revolution for creative LED displays. Whether you’re designing an irregular-shaped art installation, an outdoor interactive billboard, or a high-resolution stage backdrop, GOB LED display is more durable, visually stunning, and user-friendly.

The bottom line? You can Choose GOB if your creative project requires small-pitch resolution, operates in harsh environments, or needs long-term reliability.

For designers and brands , GOB isn’t just a technical choice, it’s a way to turn bold creative visions into durable, impactful realities.