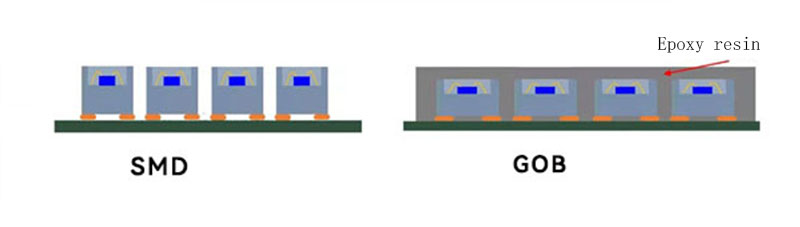

As more and more people are looking for better visual displays, some of the traditional SMD technologies just aren’t cutting it anymore. Some manufacturers have switched to COB and other new technologies, while others have upgraded the SMD technology, like GOB, which is an SMD encapsulation process that’s been improved with iterative technology. If you are looking for a high-quality GOB LED display, you may also be very concerned about its price. Let’s learn more about it.

Table of Contents

ToggleBriefly introduce the development of LED display packaging

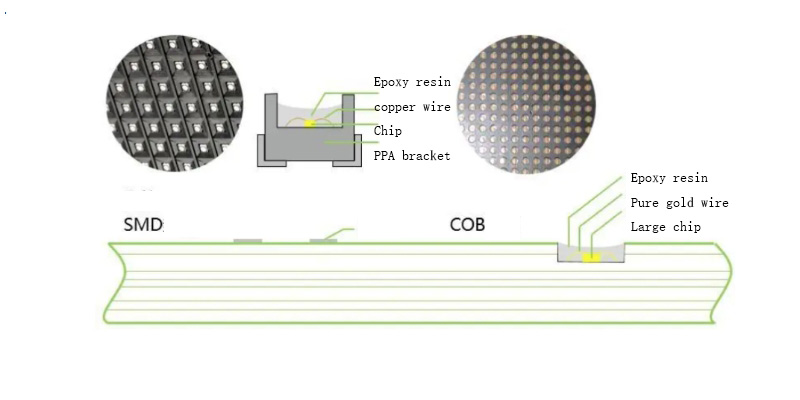

The LED display industry has come a long way, and there have been lots of different ways to produce and package the displays. From the old direct insertion (DIP) process to the surface-mounted (SMD) process to the advent of COB packaging technology, and finally to the emergence of GOB packaging technology. So, what exactly is COB and GOB technology? Let’s find out what the difference is between them!

What is GOB packaging technology?

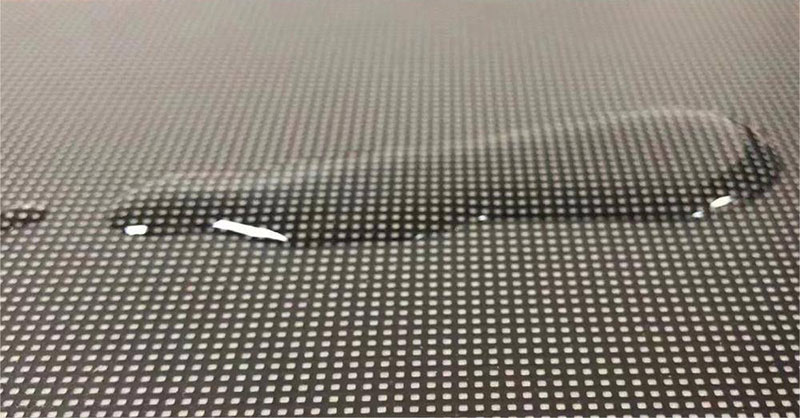

GOB stands for GLUE ON THE BOARD. GOB coating technology is a new type of optical thermal conductive nano-filling material. This technology fills the gap between the lamp beads and the PCB board of conventional LED displays, making the LED lamp beads more stable and solving the problem of dead and dropped lamps. In addition, GOB coating technology can also make the surface of an LED display look frosted, improve the existing protection technology, and come up with a new way to convert and display point light sources from surface light sources.

It uses advanced transparent materials on the PCB substrate and LED packaging unit to create an effective protective layer. This additional layer provides more features:

- waterproof, moisture-proof

- anti-impact, anti-bump

- anti-static, anti-salt spray,

- anti-oxidation,

- anti-blue light, vibration,

- anti-effects.

- Anti-vibration and other anti-effects.

What are the advantages of GOB packaging technology?

Extended life:

The shielding glue helps to dissipate heat, reduces the necrosis rate of lamp beads, makes the GOB LED screen more stable, and prolongs the service life.

Eight protective properties

Waterproof, moistureproof, anti-collision, dustproof, anti-corrosion, anti-blue light, anti-salt, anti-static.

Reduce moiré:

It realizes the transformation from point light source to surface light source, which makes the light emitting of the LED display more uniform, greatly improves the viewing angle and effectively eliminates the problem of moiré of the LED display.

Reduce visual fatigue

Its matte effect significantly improves display color contrast, reduces glare and harshness, and reduces visual fatigue.

What is COB packaging technology?

The COB package sticks directly to the chip on the PCB substrate, which makes it easier to connect the electrical parts. It was mainly introduced to solve the problem of heat dissipation in LED displays. Compared to the direct insertion type and SMD, it’s more space-saving and easier to package. It also has a highly efficient thermal management system. COB packages are mainly used in several small-pitch products.

What are the benefits of COB packaging technology?

Super thin and lightweight: We can make the PCB board as thin as 0.4mm or as thick as 1.2mm. This means we can cut down on the weight of our LED display by at least a third compared to traditional ones. In addition, we can save our customers money on transportation and engineering costs.

Anti-collision and anti-pressure: COB LED display are made by directly encapsulating the LED chip in the concave bit of the PCB board, then curing it with epoxy resin adhesive encapsulation. This makes the surface of the lamp point into a raised surface, which is smooth and hard. Therefore, it resistant to collision and abrasion.

Wide viewing angle: The COB package is used in shallow-well spherical light-emitting devices with a viewing angle of over 175 degrees, close to 180 degrees. It has a better optical diffuse color muddy light effect.

Strong heat dissipation ability: COB LED display are encased in the PCB board, with the copper foil on the PCB board quickly transferring the heat from the wick. The thickness of the copper foil on the PCB board has strict process requirements, and the immersion gold process ensures that there’s almost no light attenuation. So there are hardly any dead lights, which really extends the life.

Wear-resistant and easy to clean: The lamp point’s surface is raised into a spherical shape, making it smooth and hard. It’s also collision and wear-resistant. If there are any bad points, you can repair them one by one. There’s no mask, so you can clean it with water or a cloth.

Last in all weather: Triple protection treatment makes it waterproof, corrosion-resistant, dust-resistant, and static-electricity-resistant. It can even handle UV rays. It’ll keep working in temperatures as low as minus 30 degrees or as high as minus 80 degrees.

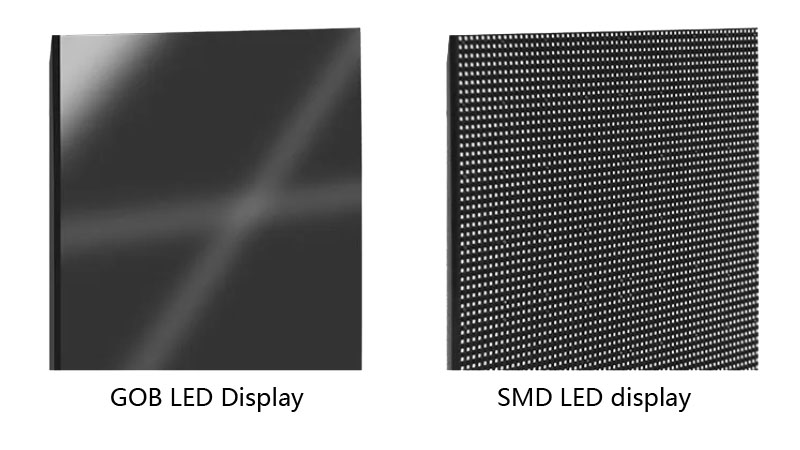

Difference between SMD and GOB LED displays

Coated GOBLED displays offer greater advantages than traditional non-gel-coated SMD LED displays:

| Term | GOB LED module | No Glue SMD LED module |

|---|---|---|

| Front | Front maintenance, P68 waterproof | No discoloration |

| Back | Rear maintenance, P68 waterproof | No discoloration |

| Maintenance | Easy maintenance | Easy maintenance |

| Module | Front maintenance, P68 waterproof | No discoloration |

| Frame | Aluminum alloy frame, 15 years | Proprietary PCB design improves thermal and electrical performance |

| Brightness, color, gray scale | Brightness, color, and gray scale adjustments do not affect each other | Brightness, color, and gray scale adjustments are highly integrated and do not affect each other |

| Application | Suitable for outdoor, high brightness | Suitable for both indoor and outdoor, high brightness |

| Lifespan | Lifespan of LEDs over 160,000 hours, lifespan of power supply over 175,000 hours | Lifespan of LEDs over 140,000 hours, lifespan of power supply over 120,000 hours |

What is the difference between COB and GOB LED screen?

The main difference between COB and GOB is the difference in process. The COB package has a flat surface and better protection than the traditional SMD package. But the GOB package goes a step further by filling the surface of the screen with glue, which makes its LED lamp beads more stable, less likely to fall, and more stable overall.

| Feature | COB (Chip On Board) | GOB (Glue On Board) |

|---|---|---|

| Technology | Directly mounts LED chips on the PCB | Adds a layer of transparent glue on the LED modules |

| Durability | High due to chip protection | Higher due to glue protection, especially from impact and moisture |

| Heat Dissipation | Better due to direct mounting | Slightly less efficient due to glue layer |

| Visual Quality | Excellent, high uniformity and contrast | Excellent, with additional protection reducing light interference |

| Maintenance | Moderate, requires handling chips | Easier, glue layer protects from dust and debris |

| Waterproofing | Not inherently waterproof | High, glue layer provides significant waterproofing |

| Anti-collision | Moderate, chips can be exposed | High, glue layer protects against collisions |

| Application | Indoor and some outdoor uses | Suitable for harsh environments, both indoor and outdoor |

| Cost | Generally higher due to complex production | Slightly lower due to added glue layer |

| Weight | Lighter due to absence of glue layer | Heavier due to the additional glue layer |

Which is more advantage: COB or GOB LED display?

GOB and COB LED displays are both good options, and there’s no one standard. Each has its own advantages, so it’s up to you to decide which is better for your specific needs, installation environment, and other factors.

In terms of small-pitch LED display, COB displays are clearly more advantageous for P1.2mm and below. However, for pitches between 1.5mm and 2.5mm, GOB displays offer a more cost-effective solution.

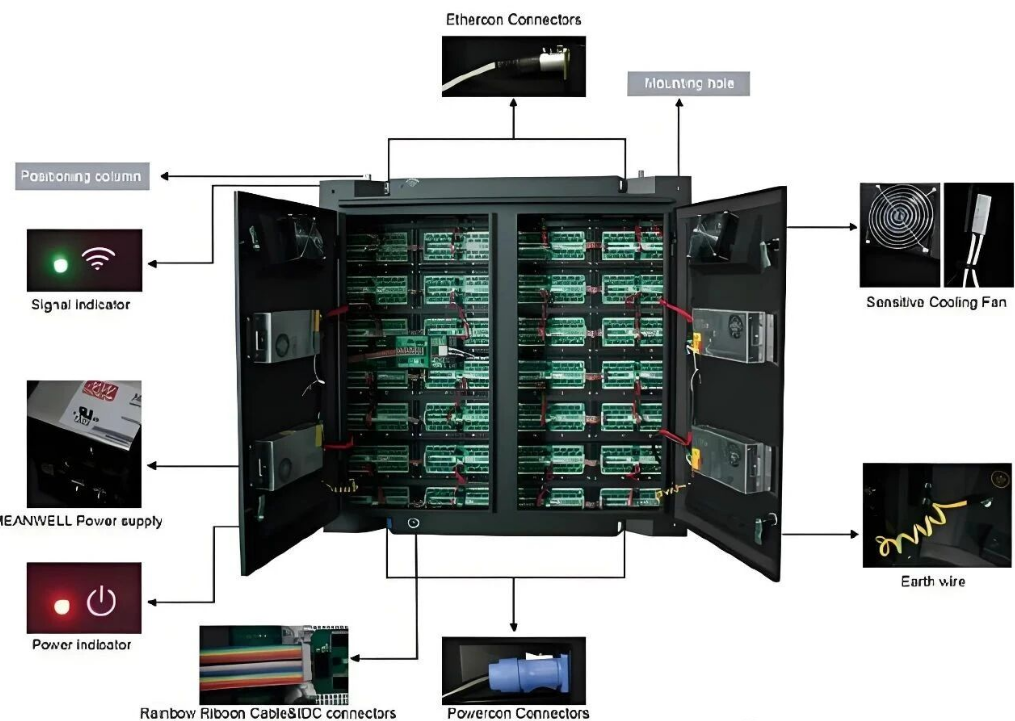

SightLED’s GOB LED display Solution:

SightLED offers GOB ED display solutions that are built to last and perform well in any environment. Here are some of the main features:

Anti-collision, anti-knock: to avoid transportation, installation, and other operations that can result in a lot of dead lights, falling lights, and other issues.

Waterproof, dustproof, moistureproof: Our GOB LED display can greatly enhance the weather resistance and protective properties, so it can be used in more harsh environments and extend the service life.

Viewing angle: You can see the LED display content from pretty much any angle. The horizontal viewing angle and vertical viewing angle can reach nearly 180 degrees.

Surface optical treatment: Our Gob LED display will reduce glare and blinding, reduce visual fatigue, and keep users safe and healthy.

Surface illumination: The Gob LED display is more uniform, and the display effect is more delicate and transparent.

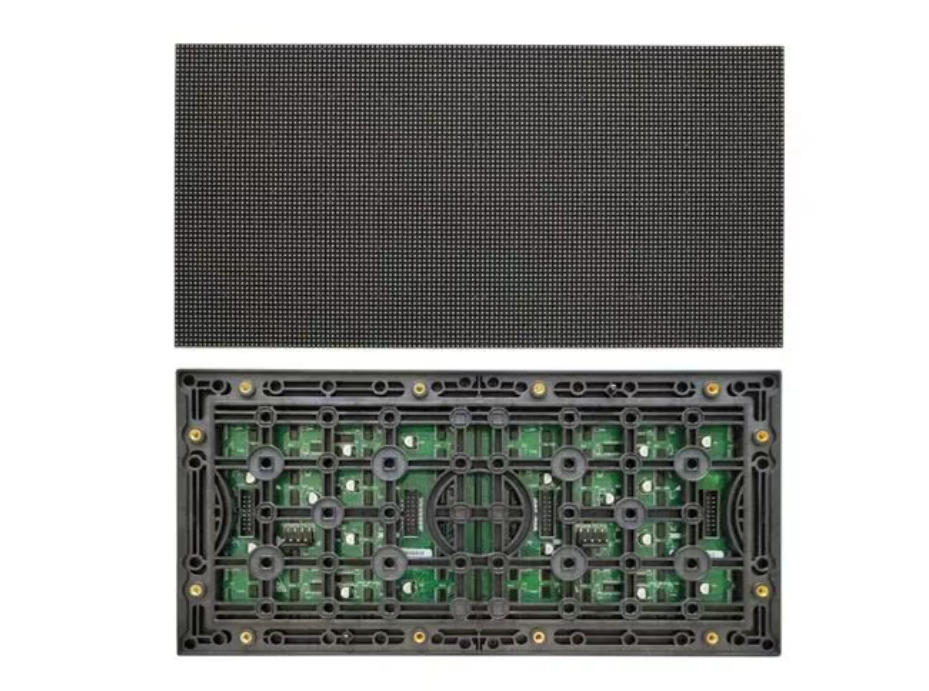

GOB LED display Specification:

| Model | P0.93 | P1.25 | P1.56 | P1.87 |

|---|---|---|---|---|

| Pixel Pitch | 0.93mm | 1.25mm | 1.56mm | 1.87mm |

| LED Type | IMD-M09 (4 in 1) | SMD1010 | SMD1010 | SMD1515 |

| Pixel Density | 1,137,777 dots/m² | 640,000 dots/m² | 409,600 dots/m² | 284,444 dots/m² |

| Brightness | 200-400cd/m² | 200-500cd/m² | 200-500cd/m² | 200-650cd/m² |

| Module Size (L×W×T) | 300mm × 168.75mm × 10mm | 300mm × 168.75mm × 10mm | 300mm × 168.75mm × 10mm | 300mm × 168.75mm × 10mm |

| Module Resolution (L×W) | 320 × 180 | 240 × 135 | 192 × 108 | 160 × 90 |

| Cabinet Size (L×W×H) | 600mm × 337.5mm × 38mm | 600mm × 337.5mm × 38mm | 600mm × 337.5mm × 38mm | 600mm × 337.5mm × 38mm |

| Cabinet Resolution (L×W) | 640 × 360 | 480 × 270 | 384 × 216 | 320 × 180 |

| Cabinet Weight | 5kg | 5kg | 5kg | 5kg |

| Working Voltage | AC: 110V~240V, 50~60Hz | AC: 110V~240V, 50~60Hz | AC: 110V~240V, 50~60Hz | AC: 110V~240V, 50~60Hz |

| Peak Power | ≤800W/m² | ≤800W/m² | ≤800W/m² | ≤800W/m² |

| Average Power | 100W/m² ~ 300W/m² | 100W/m² ~ 300W/m² | 100W/m² ~ 300W/m² | 100W/m² ~ 300W/m² |

| Viewing Angle | H: nearly 180°, V: nearly 180° | H: nearly 180°, V: nearly 180° | H: nearly 180°, V: nearly 180° | H: nearly 180°, V: nearly 180° |

| Contrast Ratio | 6000:1 | 6000:1 | 6000:1 | 6000:1 |

| High Grey Level | ≤0.0001, output is 0 | ≤0.0001, output is 0 | ≤0.0001, output is 0 | ≤0.0001, output is 0 |

| Continuous Grey Level | 0 | 0 | 0 | 0 |

| Refresh Rate | ≥0.0001, output is 0 | ≥0.0001, output is 0 | ≥0.0001, output is 0 | ≥0.0001, output is 0 |

| Operating Temperature | -10°C ~ 60°C | -10°C ~ 60°C | -10°C ~ 60°C | -10°C ~ 60°C |

| Operating Humidity | 10% ~ 90% RH, no condensation | 10% ~ 90% RH, no condensation | 10% ~ 90% RH, no condensation | 10% ~ 90% RH, no condensation |

How Much Does GOB LED Screen Cost?

The price of a GOB LED screen depends a lot on things like the pixel pitch, screen size, and other factors. We will give you a rough idea of what it’ll cost based on different project requirements.

Price per Square Meter for Different Pixel Pitches

| Model | Pixel Pitch | LED Type | Brightness | Price per Square Meter (USD) |

|---|---|---|---|---|

| P0.93 | 0.93mm | IMD-M09 (4 in 1) | 200-400cd/m² | $3,500~~$4,000 |

| P1.25 | 1.25mm | SMD1010 | 200-500cd/m² | $2,800~$3,000 |

| P1.56 | 1.56mm | SMD1010 | 200-500cd/m² | $2,200~$2,400 |

| P1.87 | 1.87mm | SMD1515 | 200-650cd/m² | $1,800~$2,000 |

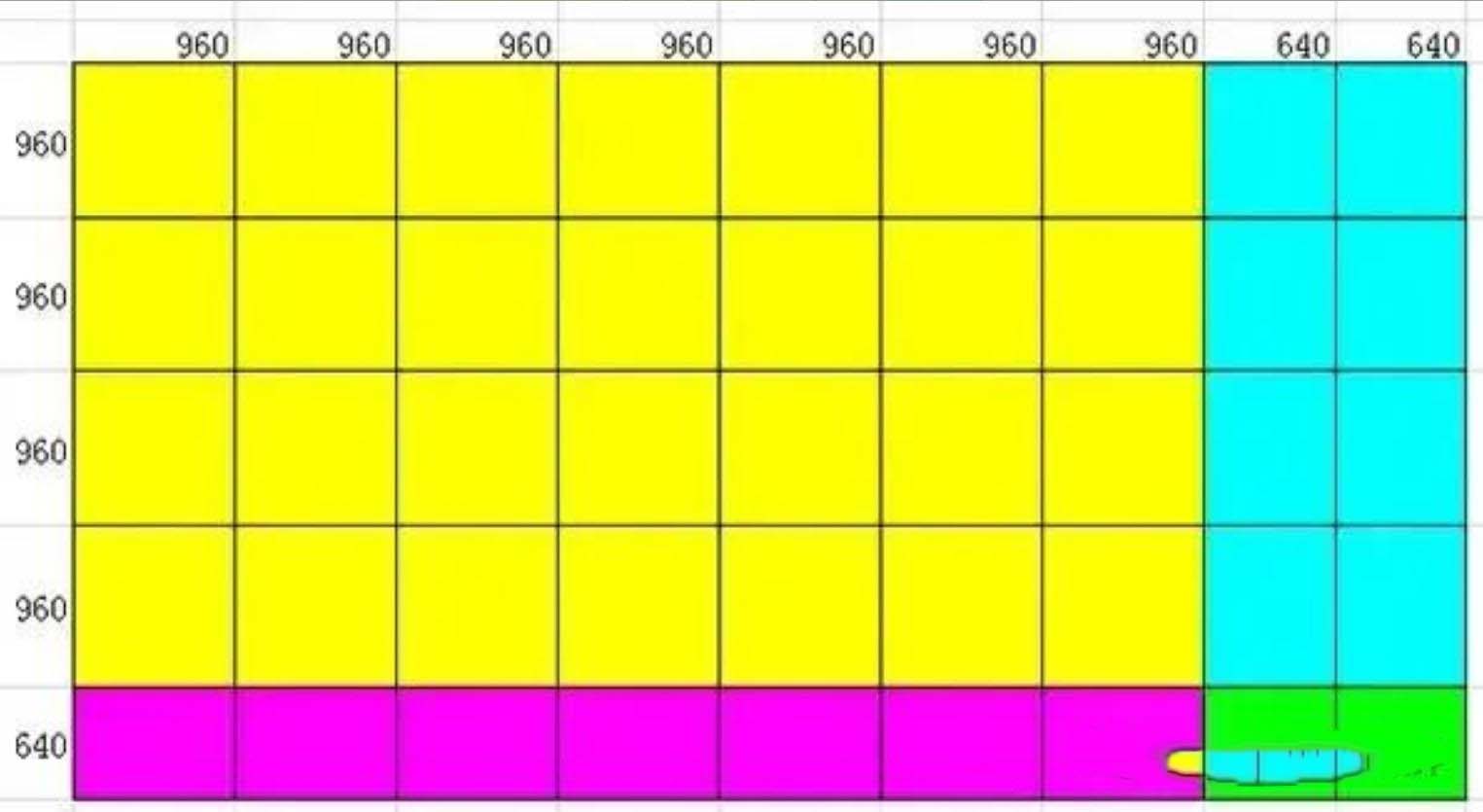

Different Area Size For GOB LED display Price

| Area Size | Approximate Price Range | Typical Applications | Example Dimensions |

|---|---|---|---|

| Up to 10 sq. meters | $10,000 to $30,000 | Small retail displays, conference rooms, small stages | 4m x 3m |

| 10 to 50 sq. meters | $30,000 to $150,000 | Medium stages, corporate lobbies, larger retail displays | 8m x 4.5m |

| 50 to 100 sq. meters | $150,000 to $300,000 | Large event stages, broadcast studios, large corporate displays | 12m x 6.8m |

| Over 100 sq. meters | $300,000 and above | Stadiums, large public displays | 18m x 10m |

Example 1:

How Much Does 3m x 2m GOB LED Display cost?

Assume a customer is looking for a 3*2 square meter indoor GOB LED display. Based on his budget, we recommend P1.56 LED display first, so the approximate cost of the project is as follows:

Screen Dimensions Calculation:

- Dimensions: 3 meters (width) x 2 meters (height)

- Area: 3m * 2m = 6 square meters

Cost Calculation:

- Cost per Square Meter: $2,200

- Total Cost: 6 sqm×$2,200/sqm=$13,2006

Example 2:

How Much Does 4m x 3m GOB LED Display cost?

Based on his budget, we recommend P1.87 GOB LED display first, so the approximate cost:

Screen Area Calculation:

- Dimensions: 4 meters (width) x 3 meters (height)

- Area: 4m * 3m = 12 square meters

Cost Calculation:

- Cost per Square Meter: $1,800

- Total Cost: 12 sqm×$1,800/sqm=$21,600

If you need more specific details, please let me know!

Conclusion:

GOB technology upgrades SMD LED encapsulation technology, which saves costs in the manufacturing process and results in higher production efficiency. As the LED pixel pitch gets smaller, the overall cost advantage of GOB LED display becomes more obvious.

In addition to the advantages of technology and cost, they also have better performance, GOB LED display lamp bad point rate is nearly an order of magnitude lower than the traditional SMD LED, better able to meet the demand for ultra-high-definition display, and has a great advantage in small-pitch display.

If you are looking for a high-quality GOB LED display, please feel free to contact us. SightLED has mature solutions on GOB LED display and many cases, we believe that we can start a new career with you.

FAQs:

How do I determine the best pixel pitch for my GOB LED display project?

It’s also worth thinking about the viewing distance. If you’re looking to get up close and personal, a smaller pixel pitch (like P1.56) will give you a higher resolution and clarity. If you’re working with larger spaces or viewing distances, a slightly larger pixel pitch (like P1.87) might be a good option. It’s also more cost-effective.

What does “P1.56” and “P1.87” mean in the GOB LED displays?

The “P” in P1.56 and P1.87 stands for pixel pitch, which is the distance in millimeters from the center of one pixel to the center of the next pixel. A smaller pixel pitch means there are more pixels packed into the same space, which makes for a clearer and more detailed image. For instance, a P1.56 GOB LED display has a pixel pitch of 1.56 mm, which is perfect for high-resolution needs and close-up viewing.

How does GOB compare to traditional LED displays?

GOB LED displays are built to last longer and be more durable than traditional SMD LED displays. The extra adhesive layer protects the LEDs, which is perfect for places where screens might get damaged.

Can GOB LED displays be used for rental and stage?

Absolutely. Since rental LED screens often need to be assembled and disassembled, thanks to the impact-resistant features of GOB technology, they are perfect for rental and stage use!

Is the visual performance of GOB LED displays affected by the adhesive layer?

The adhesive layer used in GOB LED display is transparent, so it doesn’t affect the display’s visual performance. It can also help maintain better color consistency and viewing angles.

Are GOB LED displays more expensive than traditional LED displays?

GOB LED displays cost more because they have an extra protective layer and are made in a different way. But over time, their increased durability and longer lifespan can actually save you money.