If your control room or command center is still running on old DLP projection screens, you’re missing the benefits of modern LED technology. Over the past few years, LED displays have become smaller pixel pitches, higher resolutions, and more reliable performance.

Compare to DLP and LCD video walls, they have seamless visuals, lower long-term maintenance costs, better durability, and unmatched image quality.After analyzing countless control room upgrades, we will guide you a full DLP-to-LED wall upgrade project.

Table of Contents

ToggleWhy LED Beats DLP and LCD for Control Rooms

Before we get into the specifics of the upgrade, let’s break down why LED is the clear choice for critical environments like control rooms. The difference isn’t just cosmetic. it’s about performance, reliability, and long-term value.

Seamless Visuals:

DLP projection screens and LCD video walls have a fatal flaw for control rooms: bevels (seams). LCD panels come with thin black borders around each unit. Even the smallest “ultra-narrow bezel” models have a 0.88mm gap per panel. When you splice 28 panels , those gaps create a grid of black lines.

LED displays fix this. With pixel pitches as small as 1.25mm and physical seams under 0.1mm, the human eye can’t detect where one module ends and the next begins. The result? A single, seamless canvas that shows maps, video feeds, and data without any visual interruptions.

You might’ve heard of “0mm seamless LCD” claims. Don’t be fooled. Those are just LCD panels with the bezels removed and LED strips added to mask gaps. They don’t truly eliminate seams. The brightness mismatch between the LCD panel and LED strips creates a patchy look.

Better Brightness, Contrast, and Color

Control rooms operate in all lighting condition. LED displays adapt effortlessly:

Adjustable Brightness:

LED screens let you tweak brightness based on the environment, so visuals stay clear without straining eyes. DLP and LCD screens have fixed or limited brightness ranges. In particular, LCDs wash out in bright light because they rely on backlighting instead of direct emission.

Deep Contrast:

LEDs can turn individual pixels completely off, creating true black. This makes text sharper, colors more vivid, and details in dark scenes easier to spot. DLP screens suffer from “black crush”. LCDs have poor contrast because their backlights stay on even when pixels are “off.”

Vibrant, Consistent Color:

LED uses SMD 3-in-1 technology. It delivers richer saturation and more accurate color reproduction. LCDs have limited color ranges and fade over time, making it hard to match colors across panels.

Add in LED’s 160°+ wide viewing angles and high refresh rates, and you get visuals that stay crisp from any seat in the room.

Rock-Solid Stability for 24/7 Operation

Control rooms run 24/7. Your display needs to keep up. LED outperforms DLP and LCD in durability and reliability:

Temperature and Environment Resistance: LEDs work in -20°C to 60°C, handling humidity and dust better than DLP/LCD. LCD panels are sensitive to moisture and dust, while DLP projectors overheat easily in tight spaces.

Anti-Interference:

LEDs are immune to electromagnetic interference (EMI) from nearby electronics, so you won’t get glitches or signal drops. LCDs often suffer from EMI, which disrupts video feeds.

Redundancy Features:

Our LED wall system includes dual hot-swappable power supplies and signal backups. If one power supply or signal source fails, the system switches automatically with no blackouts. Something DLP and LCD setups rarely offer.

Security:

LED supports encrypted signal transmission, preventing malicious signal cuts or unauthorized inputs. It is essential for sensitive control room operations.

Easier Maintenance, Lower Long-Term Costs

DLP and LCD are maintenance nightmares for busy control rooms. DLP projectors need bulb replacements every 2,000-5,000 hours and regular lens cleaning. LCD panels require full unit replacements if a single pixel fails. And you can’t fix just one part.

LED’s modular design changes everything:

Targeted Repairs:

If a module fails, you swap just that module (5-10 minutes) instead of the whole screen. No need to shut down operations. You can replace it while the rest of the screen runs.

Simple Troubleshooting:

Our COB LED display systems have built-in diagnostics. You can spot a faulty module, power supply, or receiver card with a quick visual check, no special tools needed.

Lower Power Bills:

LEDs use 1/10 the power of LCDs. Why? LCDs light up the entire backlight even for dark scenes, while LEDs only activate the pixels you need. For a 49㎡ screen running 24/7, this adds up to thousands in annual energy savings.

Longer Lifespan:

LEDs last 50,000-100,000 hours with minimal brightness fade. DLP bulbs burn out in 2-5 years, and LCD panels start fading after 3-4 years.

Flexible Control and Multitasking

Control rooms need to display multiple feeds at once,like video calls cameras, data dashboards, and maps. LED systems make this effortless:

Unlimited Windowing:

You can split the screen into any number of windows such as :2, 5, 8, 12, even 32 without losing resolution. DLP and LCDs limit window size and number because of their bezel constraints.

Easy Control: Manage the screen via a computer, dedicated controller, or touch panel. Switch between full-screen, split-screen, and custom layouts in seconds. No technical expertise needed.

Wide Signal Compatibility:

The system accepts HDMI 2.0, DVI, and gigabit Ethernet inputs, so you can connect computers, cameras, servers, and other devices without adapters.

The Upgrade Plan: What We’ll Do Step-by-Step

Now that you know why LED is the right choice, let’s outline the full upgrade process. We’ll keep downtime to a minimum, preserve usable equipment, and ensure the new system integrates seamlessly with your existing workflow.

Remove and Preserve the Existing DLP Screen

Your current setup has 28 DLP panels. We’ll remove them carefully, following “preserve for reuse” guidelines. Each panel will be inspected, cleaned, and packaged securely for storage. We’ll label everything clearly so you can retrieve specific panels later if needed.

Wall Restoration and Expansion

After removing the DLP screen, we’ll expand and restore the wall to match your current decor. The goal is to create a flat, stable surface for the new LED screen. It has no gaps, unevenness, or visible change to the room’s aesthetic. We’ll use matching materials and finishings to keep the space looking cohesive.

Install the New LED Display System

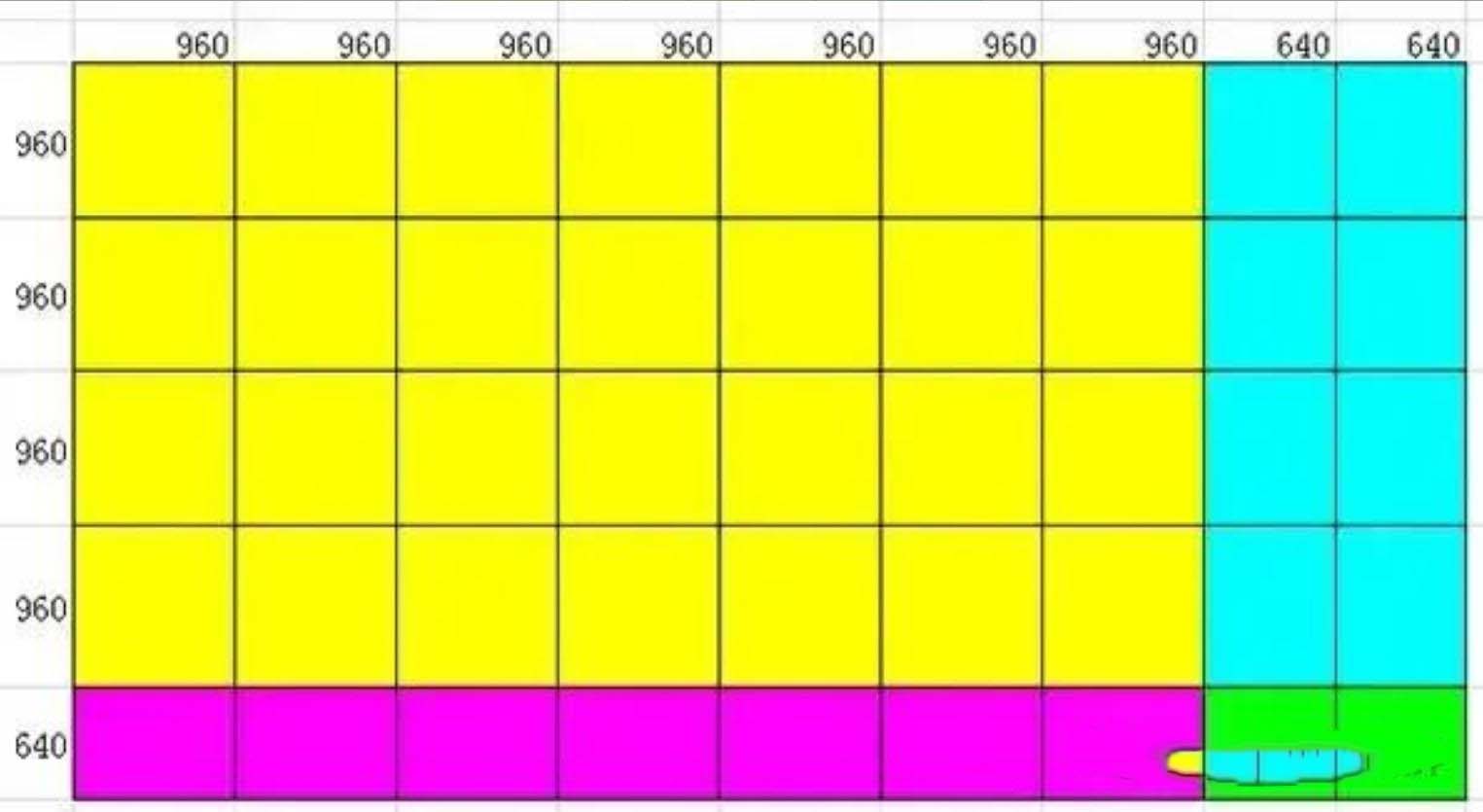

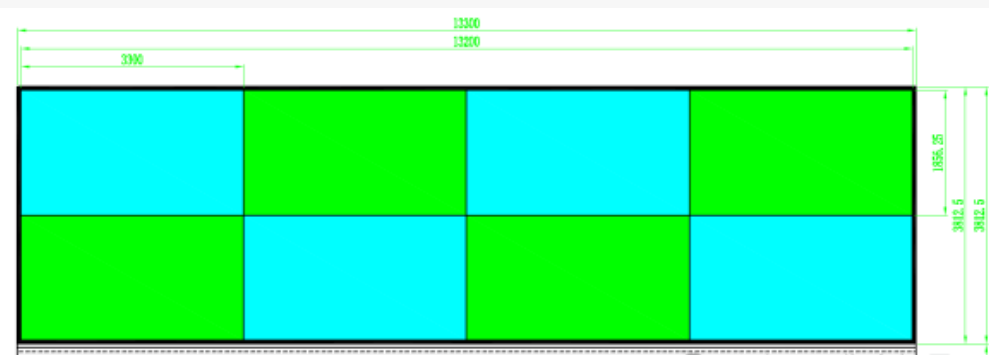

A custom LED display system fit your control room’s dimensions (12.8m wide x 3.6m high original space). We’re offering two size options:

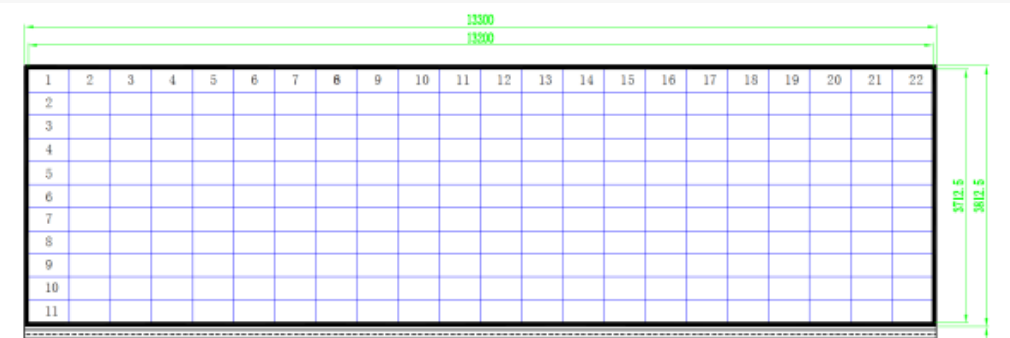

Option 1: Recommended (Standard 32:9 Aspect Ratio)

- Net Display Size: 13.2m wide x 3.7125m high

- Total Area: 49㎡

- Resolution: 10,560 x 2,970 pixels (ultra-4K)

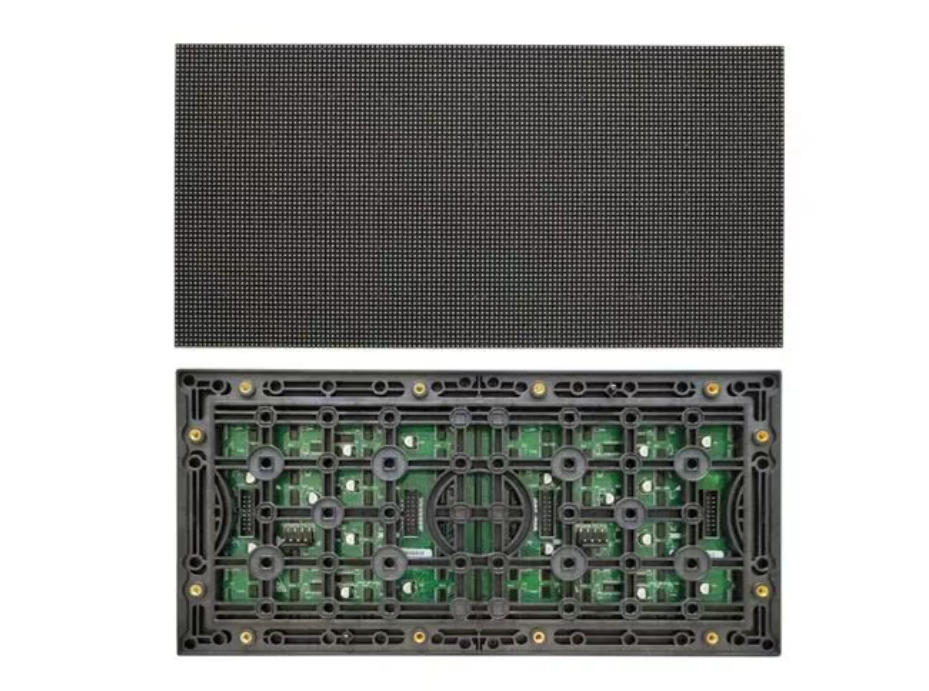

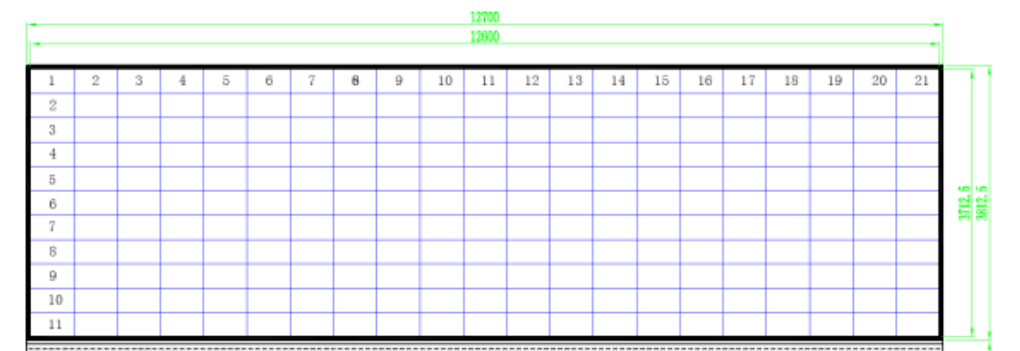

- Module Configuration: 22 modules wide x 11 modules high (each module: 600mm wide x 337.5mm high, 480×270 pixels)

Why We Recommend It:

The 32:9 aspect ratio is ideal for control rooms. It’s wide enough to display multiple feeds side-by-side without stretching or cropping. It’s also a standard format, so you won’t have compatibility issues with video calls or software.

Configuration List:

| Serial No. | Product Name | Main Specifications | Quantity |

|---|---|---|---|

| 1 | LED Display | 1. Pixel pitch: 1.25mm, pixel density: 640,000 dots/㎡; 2. Net display size: 13.2m (W) × 3.7125m (H), pixel resolution: 10560*2970; 3. 16:9 die-cast aluminum cabinet, full front maintenance; 4. Brightness uniformity ≥99%, color signal processing bits ≥24 bits, base color wavelength error ≤0.1nm, contrast ratio >10000:1, color temperature adjustable from 2000-10000K; 5. For indoor long-term viewing, display calibration brightness or white balance brightness ≥600nit(cd), brightness adjustable from 0-100%, horizontal and vertical viewing angles ≥175°, refresh rate ≥3840HZ, grayscale level: 16bit; | 49㎡ |

| 2 | Video Controller | 1. Modular design, using powerful pure hardware FPGA architecture, with stable and efficient video processing capabilities, providing excellent image quality while ensuring long-term stable system operation and virus resistance. Supports common input interfaces: HDMI, DP, SDI, DVI, VGA, CVBS; 2. Supports up to 92 channels of 1080p or 23 channels of 4K layers; 3. Input interfaces: configured with ≥32 DVI, ≥8 HDMI2.0. Chassis is expandable, supporting up to 16 channels of 4K or 64 channels of 1080P signal input. Maximum input resolution 4160X1200@60Hz, supports arbitrary resolution settings; 4. Supports maximum load of 117.96 million pixels, configured with 70 Gigabit Ethernet ports, supports redundant backup of single device output network ports, optical ports, or inter-device backup; 5. Multi-window multi-layer display, supports window roaming, free splicing; 6. Multi-screen display, window position and size can be freely adjusted; 7. Supports cropping of input signal sources, cropped signal sources can be used independently; 8. Supports connection via LAN, RS232 from computers and central control devices. | 1 unit |

| 3 | Control Software | Dedicated control software, supports unified brightness adjustment of the full screen, hardware status monitoring, configuration file recall; | 1 set |

| 4 | Intelligent Power Distribution Cabinet | 50Kw, with anti-static, lightning protection functions, power overvoltage, overcurrent, power failure protection, distributed power-on measures, supports PLC remote control; | 1 unit |

| 5 | Steel Structure, Edging, Installation, Debugging, and Training | National standard floor-standing bracket, installed, debugged, and training organized by the display manufacturer. The material and width of the display edging are provided according to user requirements; | 1 item |

| 6 | Spare Parts | Same model and batch LED beads: 2500 pieces, light board modules: 17 pieces, power supplies: 15 units, receiver cards: 10 pieces; | 1 batch |

| 7 | Main Cables, Accessory Cables, and Consumables | Main cables, accessory cables, and consumables for the electronic screen, compliant with national standard cables, with product certification provided; | 1 item |

| 8 | Other | Removal of old equipment, wall restoration, and related configuration facilities; | 1 item |

Option 2: Close to Original Size (Near 32:9 Aspect Ratio)

- Net Display Size: 12.6m wide x 3.7125m high

- Total Area: 46.78㎡

- Resolution: 10,080 x 2,970 pixels (ultra-4K)

- Module Configuration: 21 modules wide x 11 modules high (same module specs as Option 1)

Why Choose This: If you want to keep the screen size as close to your original DLP setup as possible, this is the fit. It’s slightly narrower but still delivers ultra-4K resolution and seamless visuals.

Configuration List:

| No. | Product Name | Main Specifications | Qty |

|---|---|---|---|

| 1 | LED Display | 1. Pixel pitch: 1.25mm, pixel density: 640,000 dots/㎡; 2. Net size: 12.6m(W)×3.7125m(H), resolution: 10080×2970; 3. 16:9 die-cast aluminum cabinet, full front maintenance; 4. Brightness uniformity ≥99%, color processing ≥24bit, wavelength error ≤0.1nm; 5. Contrast >10000:1, color temperature 2000-10000K adjustable; 6. Brightness ≥600nit, 0-100% adjustable, viewing angle ≥175°; 7. Refresh rate ≥3840Hz, grayscale 16bit | 46.78㎡ |

| 2 | Video Controller | 1. Modular design, FPGA architecture, stable video processing; 2. Supports 92×1080p or 23×4K windows; 3. Inputs: ≥32 DVI, ≥8 HDMI2.0, expandable to 16×4K; 4. Max load 117.96M pixels, 70 Gigabit Ethernet outputs; 5. Multi-window display with roaming and splicing; 6. Supports signal cropping and LAN/RS232 control | 1 unit |

| 3 | Control Software | Dedicated software with brightness control, status monitoring, config recall | 1 set |

| 4 | Intelligent Power Distribution | 50Kw, anti-static, lightning protection, overvoltage/overcurrent protection, PLC remote control | 1 unit |

| 5 | Steel Structure | National standard bracket, installation, debugging and training (edging material per request) | 1 item |

| 6 | Spare Parts | LED beads (2500pcs), light modules (17pcs), power supplies (15pcs), receiver cards (10pcs) | 1 batch |

| 7 | Cables | Main cables and accessories (national standard, with certification) | 1 item |

| 8 | Others | Removal of old equipment, wall restoration and related facilities | 1 item |

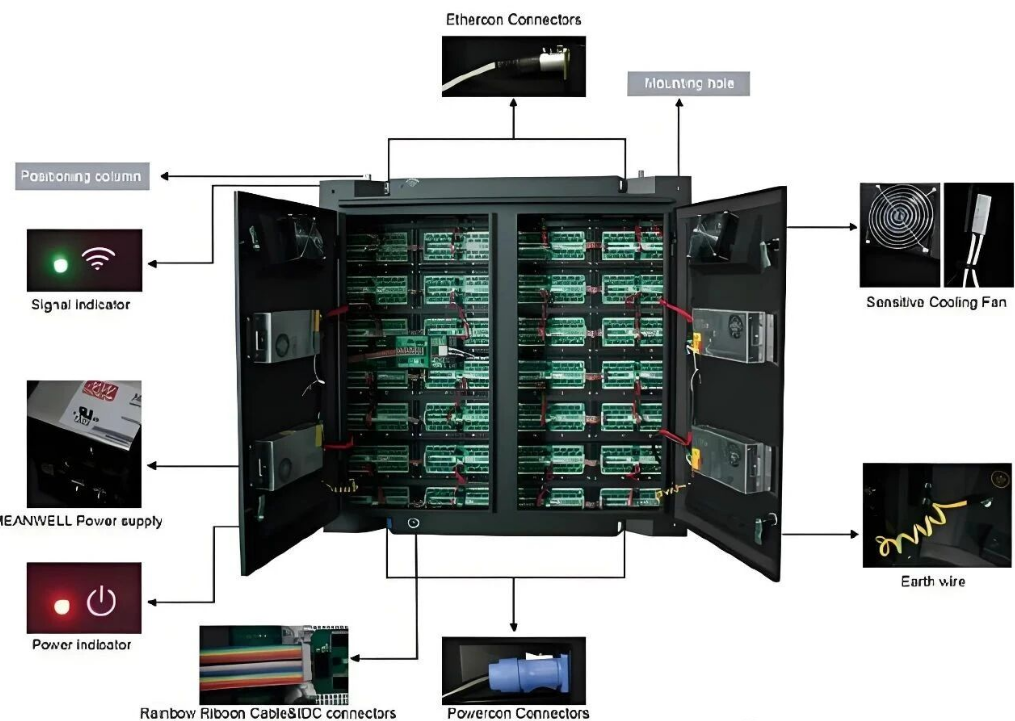

Key System Components

The LED display isn’t just a screen. it’s a complete system for reliability and flexibility. Here’s what’s included:

Video Controller

Capacity: Handles 45.5 million pixels (enough for ultra-4K+ resolutions)

Inputs: 8 HDMI 2.0 (4K), 32 DVI (2K)

Outputs: 70 gigabit Ethernet ports (Option 1 uses 66, 4 spare; Option 2 uses 63, 4 spare)

Features: Supports windowing, panning, zooming, overlaying, and signal preview. You can drag-and-drop feeds, save custom layouts, and switch between them with one click.

Power Distribution System

Smart Electrical Box: 50KW capacity with TN-S three-phase five-wire power supply (380V ±10%, 50Hz)

Key Functions:

- Step-by-step power-up/down to avoid grid shocks

- Remote on/off control (no need to manually access the box)

- Real-time power monitoring and fault alerts

- Smoke and temperature sensors (auto-shuts down if temps exceed safe limits or smoke is detected)

- Timed scheduling (auto-on/off for off-hours)

- Cabling: YJV5×16mm² cables for safe, efficient power delivery.

Steel Structure

Material: National standard square steel

Purpose: Creates a stable, level mounting frame for the LED modules. We’ll design it to fit your wall’s dimensions and weight-bearing capacity, ensuring the screen stays secure even during long-term use.

Control Software

Interface: User-friendly visual dashboard (no coding required)

Functions: Manage layouts, switch signals, adjust brightness, and monitor system health. You can access it from any computer on your network or the dedicated control panel.

How You’ll Use the New LED Screen: Common Display Modes

The beauty of the LED display system is its flexibility. You can tailor the display to your daily tasks. Here are the most common modes we’ve designed for control rooms:

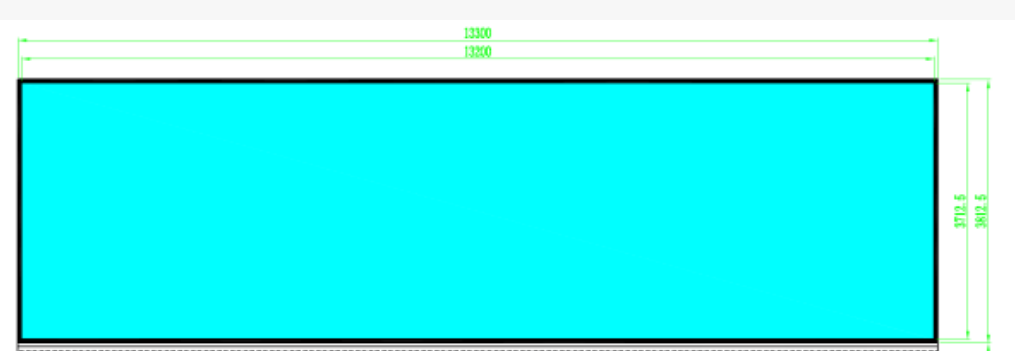

Full-Screen Ultra-4K Mode

Use Case: Presentations, training sessions, or single critical feeds ,like a high-res map.

Resolution: 10,560 x 2,970 (Option 1) or 10,080 x 2,970 (Option 2)

Why It Works: The seamless canvas makes large-format content look crisp and immersive. It do not have bevels to break the image.

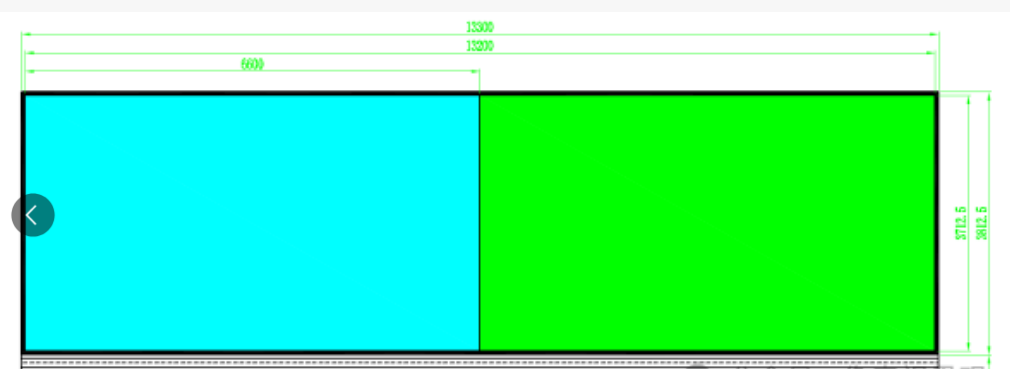

Dual-Window Mode

Use Case: Video conferences paired with data dashboards, or two critical monitor feeds.

Resolution: Each window is 5,280 x 2,970 (Option 1) or 5,040 x 2,970 (Option 2)—standard 16:9 aspect ratio for compatibility.

Why It Works: Split the screen without losing resolution—both windows stay ultra-4K, so you can read small text or spot details in feeds.

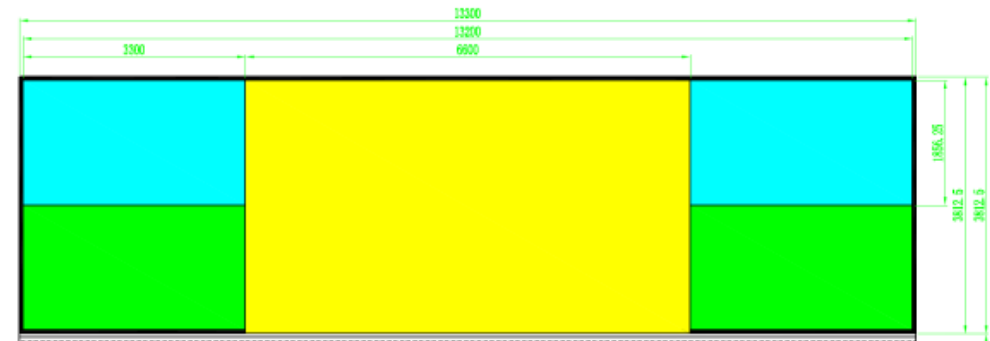

Five-Window Mode

Use Case: Multi-tasking—one main feed (e.g., a video call) plus four secondary feeds (e.g., cameras, data charts).

Resolution: 1 main window (5,280 x 2,970) + 4 secondary windows (2,640 x 1,488 each).

Why It Works: Keeps the main feed prominent while giving you quick access to supporting data. You do not need to switch between tabs or layouts.

Custom Multi-Window Modes

Options: 8, 12, 18, or up to 32 windows (all 16:9 aspect ratio).

Use Case: Monitoring multiple cameras, server statuses, or regional feeds at once.

Why It Works: You can save custom layouts for different tasks (e.g., morning briefings, emergency responses) and switch between them in seconds.

System Topology: How It All Connects

Here’s a quick breakdown of how signals flow through the system:

Your existing devices (computers, cameras, servers) connect to the video controller via HDMI/DVI/Ethernet.

The controller processes the signals, splits them into windows, and sends them to the LED modules via gigabit Ethernet cables.

The smart electrical box powers the controller and LED modules, with step-by-step startup to protect the system.

You manage everything via the control software. You can drag-and-drop windows, adjust brightness, or switch layouts.

Viewing Angle Analysis

Control rooms have multiple operators, so we’ve designed the screen for optimal visibility from every seat:

Horizontal Viewing: Clear visibility from 0° to 120° (the entire width of most control rooms). The “comfortable zone” (0° to 30°) delivers the best color and contrast, but even operators at the edges won’t see faded or distorted visuals.

Vertical Viewing: Visible from 0° to 60° (top to bottom). For seated operators (eye level ~1.2m), the screen’s height (3.7125m) ensures no one has to crane their neck—critical for long shifts.

Why This Upgrade Is Worth the Investment

We get it that upgrading a control room display is a big decision. But here’s the bottom line: this LED system will save you time, money, and headaches in the long run:

- Less Downtime: Modular repairs and redundancy mean no more shutting down operations for DLP bulb replacements or LCD panel swaps.

- Lower Costs: Energy savings + reduced maintenance = thousands in annual savings. The system pays for itself in 2-3 years.

- Better Performance: Seamless visuals, bright colors, and flexible windowing help your team work faster and make better decisions.

- Future-Proof: LED technology is here to stay. This system supports 4K+ resolutions, new signal formats, and software updates. you won’t need to upgrade again for 5-10 years.

Final Thoughts

DLP and LCD screens were cutting-edge a decade ago, but today’s LED technology delivers the seamless, reliable, and cost-effective visuals you need to operate efficiently.

This upgrade isn’t just about replacing old hardware. We’ll handle every step from removal to installation. Ready to say goodbye to bevels, frequent maintenance, and dim visuals? Let’s turn your DLP setup into a profssional LED control center. If you need an LED display screen, please feel free to contact us.