Table of Contents

ToggleWhat is the average lifespan of an LED display?

The average lifespan of an LED display depends on many factors, such as cooling system, dust protection, humidity, collision protection, load, etc. The average lifespan data of LED displays is not clearly provided in the document. However, based on the content of the document, we can infer that by using high-quality raw materials, strict aging tests, correct daily maintenance and other measures, the average life of the LED display can be extended. At the same time, taking corresponding maintenance measures for the special environment in winter, such as increasing the operating temperature, choosing better plastic raw materials, preventing static electricity and condensation, etc., will also help extend the average life of the LED display.

What are the main factors affecting the life of LED display?

The main factors that affect the life of LED displays include economic life, technical life, service life and average life. Specifically, the following aspects will affect the life of the LED display:

- Economic life: refers to the service life of the LED display at the lowest annual use cost.

- Technical life: refers to the stage from when the LED display screen is put into use on the market to when it is replaced by new technology display equipment.

- Service life: refers to the time from the LED display screen being put into use to equipment damage and failure.

- Average life span: refers to the average number of years that the LED display screen can work under normal working conditions.

In addition, the LED display life is also affected by the following factors:

- Heat: LED displays must be equipped with excellent heat dissipation systems, such as fans used for indoor and outdoor fixed LED screens.

- Dust: Dust will affect the heat dissipation of electronic components, absorb moisture in the air, and corrode electronic circuits.

- Humidity: Humidity will affect the life of the LED display. Moisture will enter precision components through packaging materials, causing internal circuit short circuits.

- Impact and scratches: During transportation or use, electronic equipment will be subject to certain impacts or scratches, which may cause damage to the LED screen.

- Load: Integrated chips, LED lamp beads, switching power supplies, etc. all need to work under rated load.

In order to extend the LED display life , the following measures can be taken:

- Use high quality raw materials.

- Conduct rigorous aging tests.

- Proper daily maintenance, such as regularly cleaning the dust on the screen and avoiding playing all-white, all-green, etc. images for a long time.

- Carry out proper maintenance in winter, such as increasing the temperature, choosing better plastic raw materials, preventing static electricity and condensation, etc.

How to improve LED display life ?

To improve the service life of the LED display, you can start from the following aspects:

- Use high-quality raw materials: Choosing high-quality LED lamp beads, IC, power supplies and other accessories can improve the performance and service life of the screen. In addition, the use of dust-free workshops and clean production lines can also reduce product failure rates.

- Strict aging test: Conduct strict aging test before leaving the factory, including white balance test, video test, etc., which can identify potential problems and extend the service life of the LED display.

- Correct daily maintenance: Clean the dust on the screen regularly and avoid playing all-white, all-green, etc. images for a long time to prevent failure caused by excessive current. At the same time, adjusting the screen brightness according to the environment can also extend the life of the screen.

- Prevent static electricity: Adding a grounding wire to the LED display, wearing an anti-static bracelet and other measures can prevent static electricity from damaging the display.

- Prevent condensation: Choosing a display with a waterproof coating can prevent damage to the display caused by condensation of water vapor in the air.

- Ensure appropriate temperature: Avoid using LED displays at too low or too high temperatures to prevent the activity of some semiconductor components from being reduced or even unable to work due to too low temperatures, as well as damage to the display caused by too high temperatures.

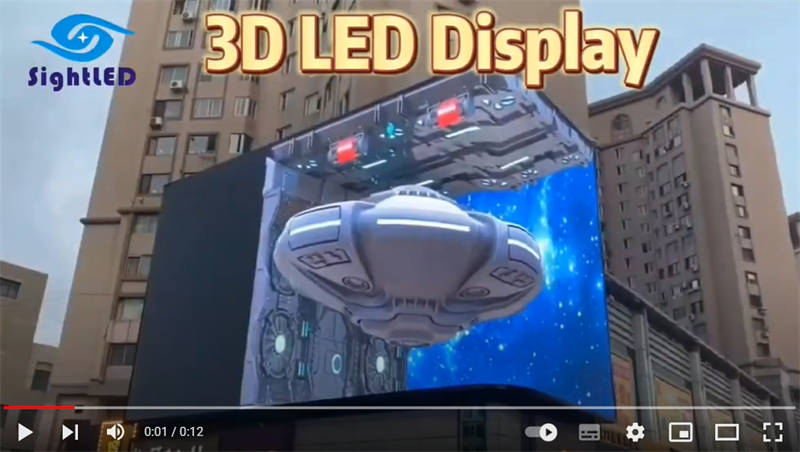

SightLED is a professional LED display manufacturer, providing high-quality and customizable indoor and outdoor LED displays for advertising, events, sports, and more. With over 12 years of experience and certifications such as ISO9001-2015, CE, and TUV, we ensure reliable post-sale services and customer satisfaction. Trust us to meet your specific needs and provide long-term quality services.

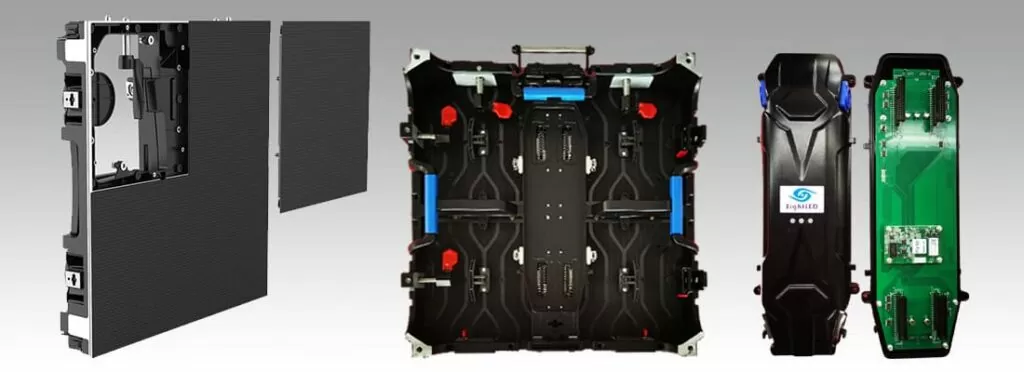

How We Make High-Quality LED Screens

Our advanced production process uses state-of-the-art equipment such as plug-in, surface mount, and wire bonder machines, automatic paint applicators, glue dispensers, and testing equipment.

We rigorously inspect every LED screen before shipment to ensure that they meet the highest standards for performance and reliability.

Explore our video showcase to see firsthand the skilled workforce and advanced machinery that make our LED screens exceptional.