Many buyers focus on pixel pitch, brightness, or refresh rate when picking an LED display. They often overlook a key internal component: the bonding wire. However, Do you know? this tiny part has a huge impact on long-term reliability and lifespan.

LED display packaging technology directly shapes product performance. Among all packaging elements, bonding wire material is one of the most discussed yet misunderstood topics. The two main options are gold wire and copper wire.

The choice between them isn’t trivial. It can decide if your screen runs smoothly for 10 years or starts failing in just a few. Today, we will guide you the differences in simple terms.

Table of Contents

ToggleWhat Is Wire Bonding in LED Display Packaging?

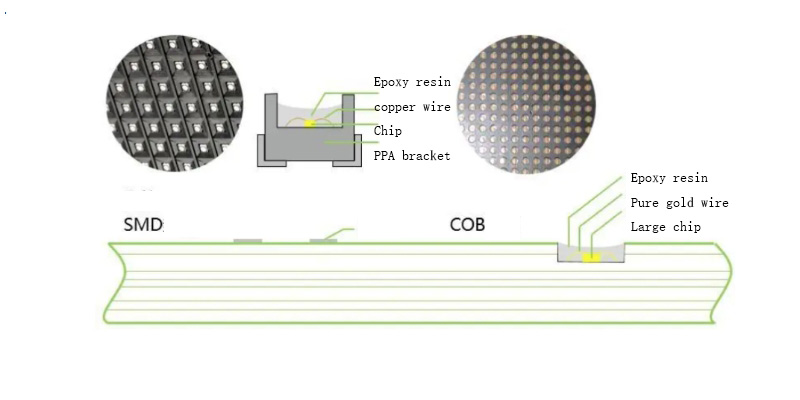

Wire bonding is an important step in LED packaging. It connects the LED chip’s electrodes to the lead frame or substrate. It uses ultra-fine metal wires to make this electrical link.

When the LED display is turned on, current flows through these wires into the chip. This current triggers the chip to emit light. The wires are very thin. It is usually measured in microns. But don’t let their size fool you.

These tiny wires have a direct impact on several key areas: electrical conductivity, signal stability, heat dissipation, mechanical reliability, and long-term service life. In most LED displays, gold wire and copper wire are the most common bonding materials.

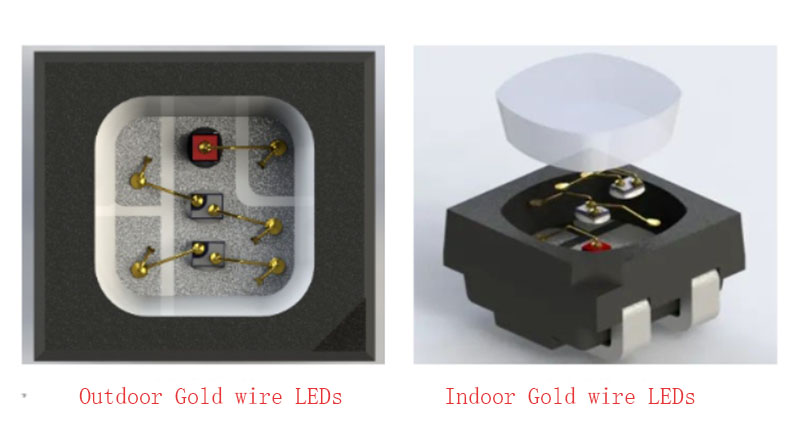

What is the gold wire encapsulation?

Gold wire encapsulation uses high-purity gold wire for the bonding process. It connects the LED chip to the lead frame.

Gold wire has been a staple in the semiconductor and LED industries for decades. Why? It offers excellent chemical stability. It also has high conductivity and reliable bonding performance.

Key characteristics of gold wire include:

- Excellent oxidation resistance

- Stable bonding interface

- High electrical conductivity

- Proven long-term reliability.

Therefore, it is a top choice for high-end LED displays that demand durability and stability.

Which LED display using gold wire encapsulation process?

Gold wire is commonly used in long lifespans and consistent performance LED displays. Common applications include:

- – Fine pixel pitch LED displays (P2.5 and below)

- – High-end indoor LED video walls

- – Outdoor LED billboards with long operating hours

- – Command centers, control rooms, and broadcast studios

- – Commercial LED displays that run 24/7

For example, SightLED often use gold wire encapsulated SMD or COB LEDs for P1.667, P1.875, P2.0, and P2.5 displays.

Our P1.667 LED display:

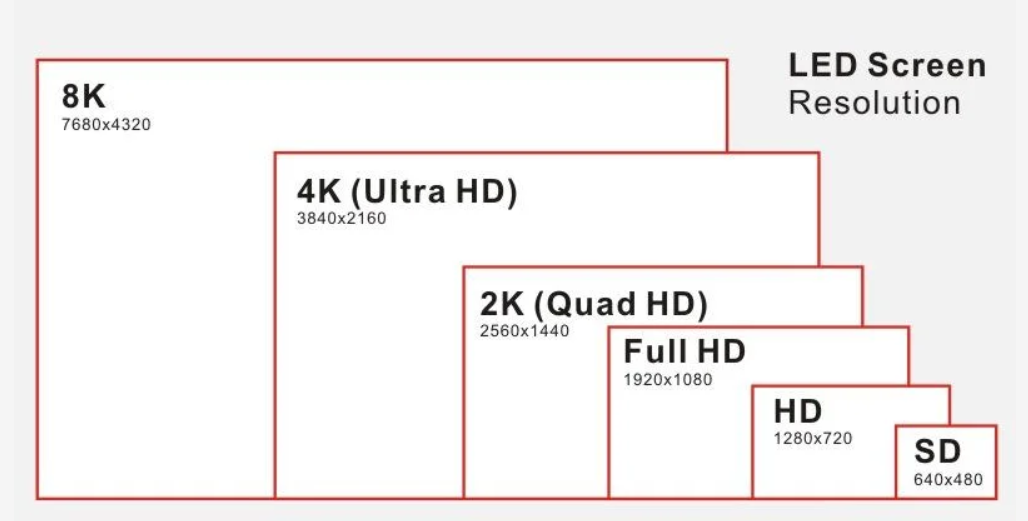

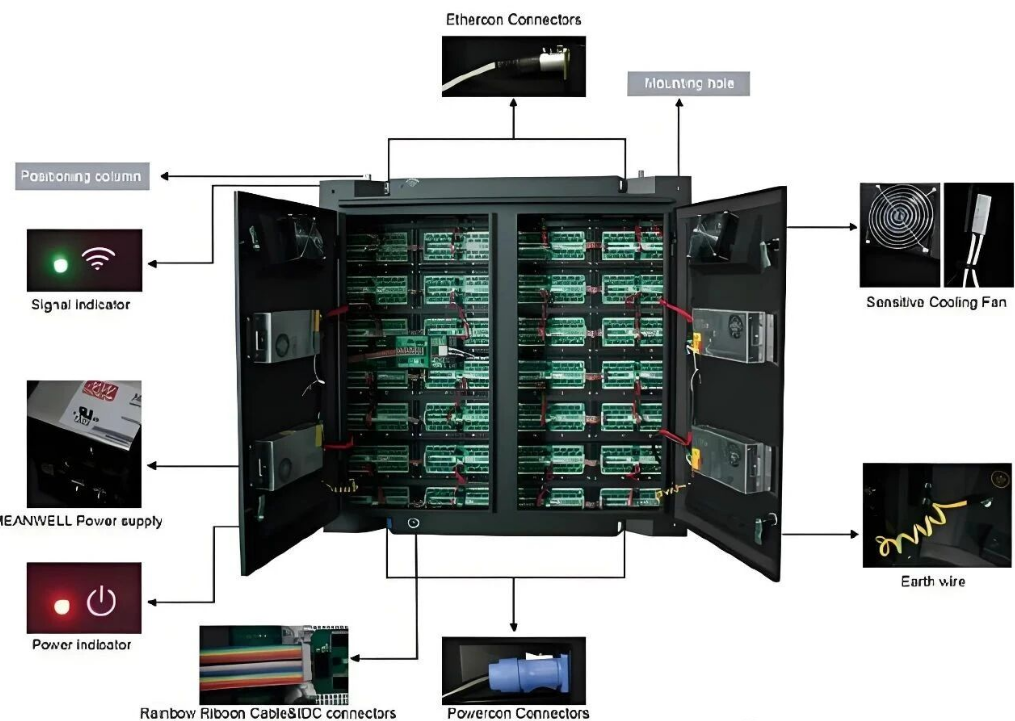

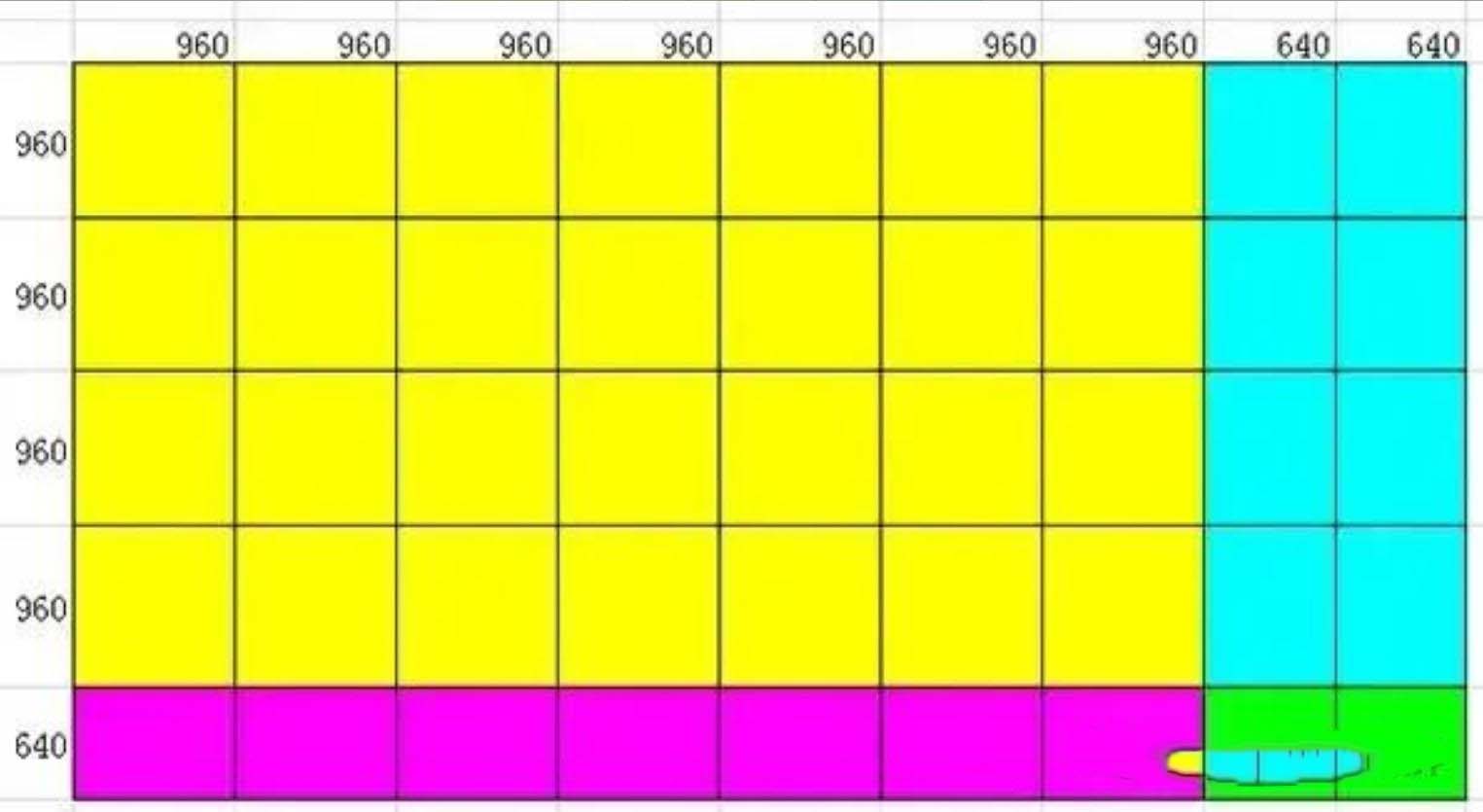

Our P1.667 small pitch LED display using gold wire encapsulation SMD1010 lamp beads, high brush driver IC. The whole screen resolution of 360,000 points / ㎡, a single cabinet ratio of 4:3. It can be spliced into a 16:9 screen, so you can enjoy the golden ratio.

In addition, the ultra-wide LED screen viewing angle of 170 ° and the picture is uniformly clear and natural. The cabinet is lightweight, easy to install and save transportation costs. The whole cabinet is only 65mm, fashionable die-casting aluminum frame design.

All in all, Gold wire encapsulation LED display is basically used for some large outdoor LED billboards, high-end indoor LED display application.

What is copper wire encapsulation?

Copper wire encapsulation replaces gold wire with copper wire for the bonding process. It connects the LED chip to the lead frame.

Copper wire gained popularity as manufacturers looked to cut costs. Copper is much cheaper than gold. It also has good electrical conductivity. Therefore, it is an attractive option for budget-sensitive markets.

However, copper wire comes with technical challenges. The biggest issues are oxidation resistance and bonding stability. These problems can affect long-term performance.

Which LED display using copper wire encapsulation process?

Copper wire is mainly used in LED displays where cost is a top priority. Common applications include:

- Budget indoor LED displays

- Small advertising screens

- Temporary installations

- Projects with short lifespan expectations

- Price-sensitive markets

You can choose common pixel pitches for copper wire displays,like regular P2.5, P3, P4, P5, and above. They’re mostly used indoors or in semi-outdoor environments with mild conditions. For Harsh environments, they are not ideal for copper wire displays.

What is the difference between gold and copper wire in LED display?

Cost:

Gold wire encapsulation LED display cost is high, mainly because the price of gold wire is expensive. Copper wire encapsulation, on the other hand, has become the preferred choice for many cost-sensitive applications due to its lower cost. The copper wire cost is usually only one-third or even less than the cost of gold wire, which has a significant cost advantage for mass LED displays.

Oxidation resistance:

Gold wire has excellent oxidation resistance, which can maintain a stable connection in harsh environments. In contrast, copper wire is more susceptible to oxidization, resulting in poor connection or metal deformation, thus affecting theLED display qualification rate and service life. Therefore, in the high-end or the need for high reliability in the application, the gold wire package is more suitable.

Solder contact:

Gold wire encapsulation in the solder contact is excellent, to ensure stable connection between the chip and the bracket. Due to material characteristics, the copper wire may not be easy to tightly combined with the bracket, resulting in crescent cracks or damage to the solder joints and other issues. This not only affects the quality of the secondary welding, but also may increase the risk of reliability in the process of customer use.

Thermal conductivity:

Although thermal conductivity is not a direct characteristic of the encapsulated wire, but the thermal conductivity of copper wire is better than gold wire. In high-power LED applications, good thermal conductivity helps to dissipate heat quickly and improve the efficiency and stability of the LED display. However, in most LED display applications, electrical conductivity and oxidation resistance are usually more critical factors.

| Parameter | Gold Wire LED Display | Copper Wire LED Display |

|---|---|---|

| Material Cost | High | Low |

| Oxidation Resistance | Excellent | Moderate to Poor |

| Bonding Stability | Very High | Lower |

| Failure Rate | Low | Higher over time |

| Service Life | 8–10+ years | 5–7 years |

| Environmental Adaptability | Strong | Limited |

| Typical Applications | High-end indoor & outdoor | Budget indoor displays |

Reliability and Lifespan Analysis

From an engineering perspective, reliability is the biggest difference between gold and copper wire displays. This difference becomes more obvious over time.

Gold wire forms a stable intermetallic compound (IMC) with the bonding pad. This compound have a strong, durable electrical connection. It stays stable even after years of exposure to heat and humidity.

Copper wire is more prone to oxidation and micro-corrosion. As time passes, oxidation increases resistance at the bonding point. This can lead to several issues:

- – Flickering pixels

- – Partial LED failure

- – Dead pixels

- – Reduced brightness uniformity

In long-term projects, these problems push up maintenance costs. They can also disrupt the display’s performance.

Oxidation Resistance and Environmental Adaptability

Gold is a noble metal. It doesn’t oxidize easily. Therefore, gold wire LED display are perfect for harsh environments, such as:

- – Outdoor LED displays

- – High-humidity areas

- – Coastal regions or industrial zones

Copper wire oxidizes quickly when exposed to moisture and oxygen. Once oxidation happens, the bonding interface becomes unstable. It will increase the risk of open circuits.

For this reason, we are not recommended copper wire displays for long-term outdoor use. They work best in dry, stable indoor environments.

Bonding Strength and Mechanical Stability

Gold wire has excellent ductility and bonding strength. It can absorb thermal expansion and mechanical stress during operation.

Copper wire is harder and less flexible. During thermal cycling, its bonding points are more likely to develop micro-cracks.

Mechanical stability directly affects long-term reliability. A display with weak bonding points will fail sooner than one with strong, flexible connections.

Electrical and Thermal Performance Differences

Copper has slightly better thermal conductivity than gold. In theory, this helps with heat dissipation. But in LED displays, the bonding wire isn’t the main path for heat transfer.

Most heat is transferred through the LED substrate, PCB, and cabinet structure. So, copper wire’s thermal advantage has little practical impact.

The difference in electrical conductivity between gold and copper is also negligible. Reliability is the far more important factor here.

How to choose gold or copper wire LED display?

When choosing gold or copper wire encapsulation LED displays, it is necessary to make comprehensive considerations based on the actual application and performance requirements. For high-end applications, if you need high reliability and long life, gold wire LED display is a better choice. For lower budget or the low-end market, copper wire LED display are more attractive due to their cost advantages.

Gold wire and copper wire encapsulation LED displays each have their own unique advantages and application. With the continuous progress of technology and cost optimization, these two encapsulation technologies will continue to play an important role in LED display. In the future, with the emergence of new materials and new processes, we are expected to see more innovative LED display solution.

Application Scenarios: When Gold Wire Is Necessary

We strongly recommended Gold wire for the following scenarios. In these cases, long-term reliability is more important than initial cost savings:

- – Outdoor LED billboards (especially those running 24/7)

- – Fine pitch LED video walls

- – High-end commercial LED displays

- – Control rooms and monitoring centers

- – Broadcast and studio environments

If you are choosing gold wire here, it can reduce the risk of downtime and maintenance costs. It ensures the display performs consistently for years.

Cost vs Performance: Is Gold Wire Worth It?

Gold wire displays cost more upfront. But they offer long-term benefits that often make them worth the investment. These benefits include:

– Lower failure rate

– Reduced maintenance costs

– Longer service life

– Better return on investment (ROI) over time

For short-term projects ,such as 1-2 year temporary event, copper wire may be sufficient. But for long-term installations, gold wire is often more cost-effective. It avoids the high replacement and maintenance costs of copper wire displays.

Common Misunderstandings About Copper Wire LED Displays

There are several common myths about copper wire LED displays. Let’s clear them up:

– Myth 1: Copper wire immediately reduces LED brightness. Fact: Short-term brightness is similar to gold wire. The difference appears over time as oxidation affects performance.

– Myth 2: Copper wire displays are just as reliable as gold wire. Fact: Reliability issues usually show up after years of use. They’re not obvious at first.

– Myth 3: Copper wire can be used outdoors with no issues. Fact: Outdoor environments accelerate oxidation. This leads to faster failure.

Conclusion:

In short, If you can understand the characteristics and differences between gold wire encapsulation and copper wire encapsulation ,it will help us better choose the LED display. SightLED, as a professional LED display manufacturer, we provide copper wire and gold wire LED display solutions. If you need LED display, please share your ideas, we will give you a more reasonable solution, contact us today.

FAQs:

Q: Is gold wire necessary for indoor LED displays?

A: It depends on the application. For fine pitch and high-end indoor displays ,like control rooms, yes. For budget indoor screens with short lifespans, copper wire may be enough.

Q: Does copper wire reduce LED brightness?

A: Not initially. But oxidation can affect long-term stability. It may lead to reduced brightness or uneven lighting over time.

Q: Can copper wire be used outdoors?

A: It’s not recommended for long-term outdoor installations. Harsh weather speeds up oxidation and bonding failure.

Q: Is alloy wire a better choice than both gold and copper?

A: It’s a compromise. Alloy wire is cheaper than gold and more reliable than copper. But it still can’t match gold’s long-term stability for critical projects.