In today’s display technology field, there are many misunderstandings about small-pitch COB LED screens in the market. On the one hand, some people think that this is an “expensive” technology; on the other hand, some people think that traditional SMD technology is “already enough”. The new technologies may not have much room for development. However, since 2016, the rapid development of COB small-pitch LED screens in the high-end market has strongly proved the truth that “technological innovation has no limits.”

Table of Contents

ToggleWhy is COB LED Display so popular?

As one of the leaders in LED screens, SightLED launched the COB small-pitch LED screen in the second half of 2020. In just over a year, it has received more than 50+ orders from high-end command and dispatch centers. It can be said that COB small-pitch technology has undertaken most of the growth of SightLED’s indoor screens.

Take the COB small-pitch display and control system provided by Sight LED for Beijing project as an example. The user hopes to transform from a decentralized and relatively independent office mode to an overall and comprehensive centralized office mode. To this end, Sight LED provided P1.2 COB display and control system. Its targeted construction schemes such as curved surface design. They are more suitable for the use environment of the project with a large number of office staff and diverse and complex information.

From the perspective of the industrial chain, since the second half of 2015, China LED packaging and testing companies have entered a large-scale expansion cycle. The new production capacity has been arranged on COB packaging technology. This is not only because of the accelerated development of COB LED display applications, including lighting applications, mobile phone and TV backlight applications, etc., have also entered the COB chip-level packaging era.

At the level of basic LED wafer manufacturers, the development of small-particle high-brightness crystals is also becoming more and more abundant. Taiwanese companies attach great importance to the potential of this market. They believe that MINI-LED technology will be one of the main directions of the short-term LED application incremental market.

It can be said that the rise of COB technology is not isolated, but a resonance of the entire industrial chain. From upstream chips, packaging to downstream applications, as well as equipment and material manufacturers, they are all supporting the development of COB products.

The overall optimism of the industrial chain must mean that COB technology has its unique advantages. These advantages are also the key to the rapid implementation of COB products in the large-screen market.

Core advantages of COB LED screen

Stronger stability

COB packaging technology adopts chip-level packaging technology. LED crystal particles directly contact the PCB board, which enhances the heat dissipation capacity and improves the durability of the product. At the same time, COB packaging forms a 100% protective layer on the LED crystal, which has good moisture and bump resistance. In contrast, SMD LED displays need to undergo high-temperature reflow soldering, which can easily cause damage to the lamp beads and affect the service life. COB technology does not require reflow soldering, and its dead lamp rate is only one-tenth of SMD packaging, and the stability is greatly improved.

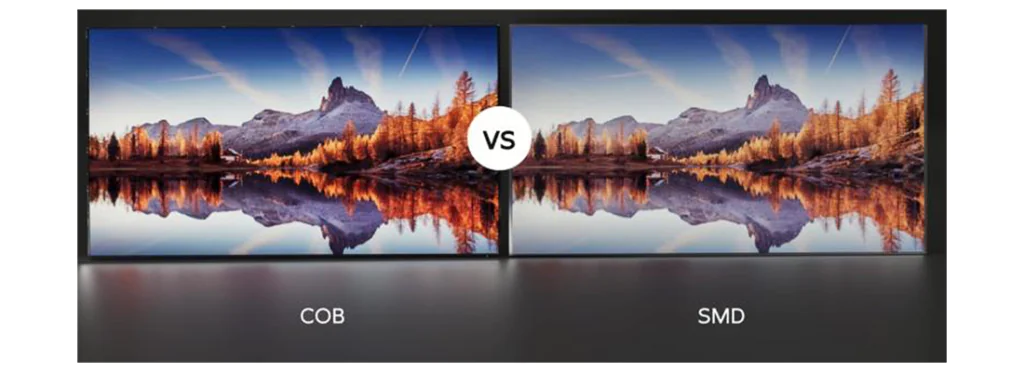

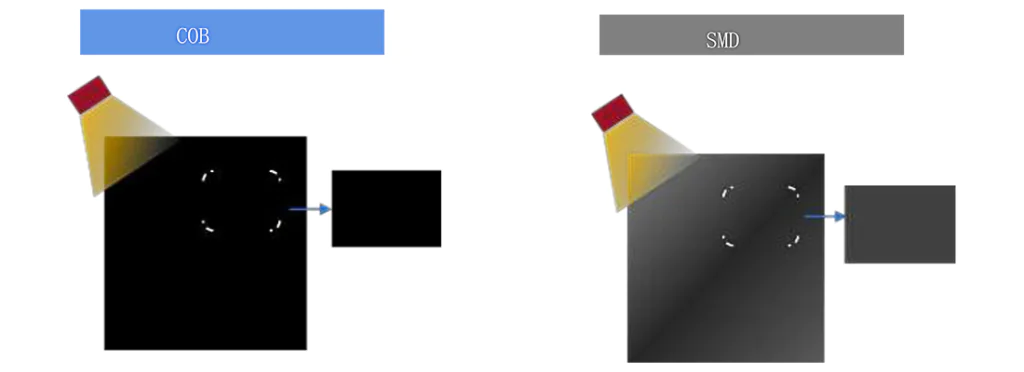

Better visual experience

Small-pitch COB LED technology adopts chip-level packaging and optical resin full coverage structure. Compared with traditional SMD lamp beads, it has better visual performance. Although the LED screen has high brightness, traditional surface-mount products are prone to glare, granularity and high-frequency flickering, which makes viewers prone to visual fatigue after long-term use. COB technology can effectively reduce glare and make the picture softer and more delicate.

Users can intuitively feel the advantages of COB technology in visual experience by comparison. The characteristics of high definition and low glare make COB products popular in the high-end market.

How COB leads the future development of small-pitch LEDs

The development direction of small-pitch LED screens has always been to reduce the pixel pitch, but when the pitch is reduced to 0.7mm or even 0.8mm, traditional SMD technology has encountered bottlenecks in mass production and market application. Therefore, to further promote the development of small-pitch LEDs, we must rely on more advanced packaging processes, and COB is the core of this change.

Lower bad pixel rate

COB packaging technology can effectively reduce the bad pixel rate, which is only one-tenth of the SMD process. Therefore, it has more advantages in the market application of high-pixel density products.

More cost advantage

COB packaging technology directly skips the “lamp bead packaging” step in the SMD surface mounting process, making the production process more simplified.

On P1.5 pitch LED display, SMD still has a certain price advantage, but on P1.0 and below pitch display, the cost advantage of COB technology will gradually emerge. Therefore, as LED screens develop towards smaller pitches, the advantages of COB technology in cost control will be more obvious.

Adapt to smaller LED crystal particles

The continuous progress of LED light-emitting technology has enabled smaller LED crystal particles to reach acceptable standards in terms of brightness and heat dissipation.

COB technology has significant advantages in integrating smaller LED crystal particles due to its packaging characteristics. Therefore, COB packaging will become the key to the future LED display industry to cope with higher pixel density requirements.

Recognition of international manufacturers and R&D trends

As a LED display manufacturer, when choosing a technical route, future development space is a very important factor. As LED display screens develop towards smaller pitches, SMD technology encounters bottlenecks, and COB technology has obvious advantages in achieving small/micro pitches on LED display screens.

In fact, international manufacturers have also given high recognition to COB technology. In 2017, Samsung strengthened the promotion of small-pitch LED screens in the digital film projection market, and Sony increased the promotion of small-pitch LED screens in the production-level film and television market. These two giants are without exception supporters of packaging-level technologies such as COB.

From the perspective of product research and development, Sony demonstrated LED screen products based on MINI-LED particles, chip-level packaging, and only 0.5 mm pitch in 2012. The upstream LED industry in Taiwan, my country, believes that the “screen application” of MINI-LED products, including small-pitch LED screens and direct-type LCD backlight products.

Policy support and future prospects

In September 2017, the China Ministry of Science and Technology reported that COB is the future development direction of small-pitch LEDs. The scientific community will invest huge amounts of money to break through the shortcomings and limitations of traditional small-pitch LED display technology.

COB screens have not only been chosen by international manufacturers, recognized by the upstream industry, and supported by the government. Therefore, COB technology must be the key development direction of small-pitch LED products in the future. This is also the core reason why the industry calls COB the second-generation product of small-pitch LED screens.

Of course, even if it is a very good technology, COB LED video wall cannot occupy the entire market right away. Starting from the high-end and gradually popularizing, this process has also been the “path” of surface-mounted small-pitch LED large-screen products in the past 6 years. However, now it is the turn of COB screen to once again interpret the “market iteration” process of occupying the high-end first and then popularizing.

With the continuous advancement of technology and the gradual maturity of the market, small-pitch COB LED screens are expected to be widely used in more fields, such as commercial displays, conference rooms, control centers, etc.

Its high stability, good visual experience and ability to cope with extremely small pitch challenges will bring users better display solutions. At the same time, the coordinated development of upstream and downstream enterprises in the industrial chain will further promote the innovation and improvement of COB technology, enabling it to occupy a more advantageous position in future market competition.

Related:

Conclusion:

In short, with its unique advantages, the COB technology LED screens is carrying the banner of the future and leading the small-pitch LED screen industry into a new stage of development. We have reason to believe that in the near future, COB LED screens will become the mainstream product in the display market, bringing more convenience and surprises to people’s lives and work. If you need COB LED screens, please feel free to contact us.